Date : March 19 - 20, 2019

Notice: G20 Osaka Summit Press Tour (Osaka and Hyogo)

post date : 2019.04.08

Kansai: A Pillar of the Japanese Economy

<Companies Shining in Niche Markets>

<Companies Solving Issues with Advanced Disaster Prevention Technology>

The G20 Summit, where world leaders from advanced and emerging economies gather to discuss economic issues such as the global economy, trade, investment, and development, will be held in Japan for the first time on June 28 and 29 this year in Osaka.

The sustainable growth of the global economy is supported by the actions of diverse businesses contributing to people’s lives and a safe society, with technology and products being developed to accurately meet the needs of society and the market through tireless research and development. Osaka, where the summit will be held, is home to the world’s oldest business still existing, and was known as the “kitchen of Japan” in the Edo period due to being a center for the trade and distribution of products from around the country. The city prospered as one of the centers of the Japanese economy. Currently, the economy of Kansai, with Osaka as its focus, accounts for approximately 20% of the Japanese economy, with a nominal GDP of 714 billion USD (in 2015) making it half the size of South Korea’s (1,383 billion USD) and close to the GDP of the Netherlands (758 billion USD). The rate of new business formation in the two years since 2016 was the highest in Japan, higher than Kanto, with many companies making their presence felt with original, unique technology.

This tour will visit Osaka and Kansai (Osaka and Hyogo prefectures) 100 days before the start of the G20 Summit to cover companies with a strong presence in niche markets and companies solving issues with new technology using their experience from major disasters such as the Kobe Earthquake, seeing the industrial strength that is the source of Kansai’s vitality.

Tour Details (subject to change)

<Summit Venue>

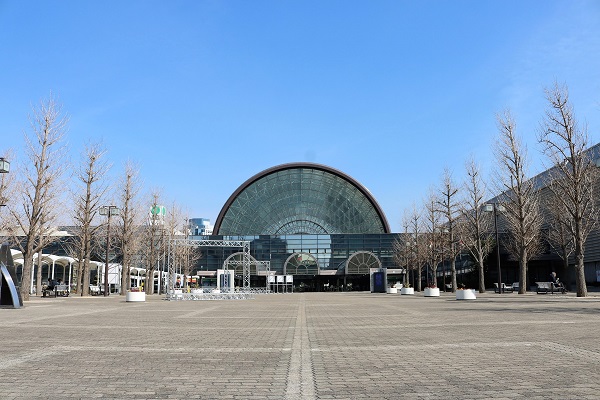

International Exhibition Center, Osaka (INTEX Osaka)

INTEX Osaka, which will be used as the venue for the G20 Summit, is the largest exhibition center in western Japan with an exhibition area of over 70,000 square meters. It is built on Sakishima, an artificial island made of reclaimed land in 1980.

It is connected by the Yumesaki Tunnel to Yumeshima, which will be the venue for the 2025 Osaka Expo.

There will be an opportunity to film and photograph the interior of INTEX Osaka. Afterwards, the tour will go to the Sakishima Cosmo Tower observation deck, located 252 meters above ground, where it will be possible to film and photograph INTEX Osaka, Yumeshima, and the city of Osaka through the windows.

*Since there will likely be restrictions placed on entry to INTEX Osaka as the summit approaches, we suggest using this chance to take videos and photos.

<Companies Shining in Niche Markets>

1. Kongo Gumi Co., Ltd.

This company, which specializes in building temples and shrines, was established in 578, and with 1440 years of history is the oldest company still existing. The company was founded by one of three craftsmen invited from Baekje (a Korean kingdom) to build Shitenno Temple, Shigemitsu Kongo, who became its official carpenter in charge of protecting, rebuilding, and repairing the temple. Since the Meiji period (1868–1912), the company has also built and restored traditional architecture such as Buddhist temples and Shinto shrines throughout Japan.

Kongo Gumi has a total of 100 carpenters divided into eight groups, called Takumi-kai, and these groups each work at different sites throughout Japan. Before going to the work site, they draw a full-size blueprint by hand in order to cut wood to the perfect size and give it beautiful curves. It is said it takes 30 years of experience to be able to draw one of these blueprints. Construction that does not rely on nails or metal is also a unique feature of this traditional Japanese construction method.

The tour will visit Kongo Gumi’s Kansai processing center (in Sakai), and hear from President Kenichi Tone about the company’s history and the meaning of its business to society, as well as future plans.

The tour will also have the opportunity to film a full-size blueprint and pieces being processed, guided by Mr. Shigeo Kiuchi, a carpenter who appeared in the American documentary Takumi: A 60,000 Hour Story On the Survival of Human Craft which was released last year.

2. Hardlock Industry Co., Ltd.

Higashiosaka, a city located in eastern Osaka with a population of around 500,000 is known for its approximately 6,000 workshops that produce a wide variety of products (nationally, it is ranked 5th for the number of workshops by city, right after Yokohama). It has the highest density of businesses in Japan, with approximately 115 business per square kilometer of habitable land. The area is also unique as instead of a pyramid structure with major businesses at the top, 90% of the businesses are independent, creating unique products.

Since its founding in 1974, Hardlock Industry is a business that has focused on making the most secure nuts in the world. Nuts and bolts are used to fasten two parts together. The Hardlock Nut developed by Katsuhiko Wakabayashi, the founder and president of Hardlock Industry, combines a convex nut and a concave nut of different shapes, and by tightening the concave nut around the concave nut which acts as a wedge, a powerful locking effect occurs. Since it is no longer necessary to perform maintenance to tighten loosened nuts, and accidents in which the bolt breaks due to loosened nuts can be avoided, these Hardlock Nuts are used in a variety of situations.

Despite Hardlock Industry being an SME with only 90 employees, Hardlock Nuts are used in infrastructure throughout the world: in high-speed trains around the world including not only Japan, but Australia, Taiwan, and the UK; in major bridges such as the Great Seto Bridge; in space shuttle launch pads in the US; and in the Tokyo Skytree. Approximately 20,000 bolts are used in a 16-car Shinkansen train. Hardlock Industry sells approximately 25 million sets of nuts annually, with annual sales of 2.1 billion yen. Currently, they are developing nuts for use in dental implants and satellites, and are aiming to enter the aerospace industry.

Mr. Wakabayashi will explain how the Hardlock Nut prevents loosening, and what led to the development of this long-selling product. There will also be a demonstration of applying vibration to both bolts using Hardlock Nuts and bolts using other nuts, to evaluate the loosening of the nuts and their ability to prevent loosening.

3. Kawamura Gishi* Co., Ltd.

Kawamura Gishi’s headquarters are located in Daito, in eastern Osaka. While most prosthetics and orthotics makers in Japan are small workshops with only a dozen or so staff, Kawamura Gishi has 160 staff just in its manufacturing division, making it one of the larger companies in the industry.

Kawamura Gishi custom makes prosthetics to replace limbs lost due to illness or accident, and orthotics for healing, prevention, and to support the recovery of physical capabilities.

To ensure the timing to begin rehabilitation is not missed, the company uses their advanced techniques and their experience dealing with numerous conditions to quickly create prosthetics and orthotics of high quality.

The company has also been involved in manufacturing seats and other items used in parasports.

Kawamura Gishi will be supporting approximately 20 athletes in 8 events for the Tokyo Paralympics which will take place next year.

President Kei Kawamura will show the tour the manufacturing process for prosthetics and orthotics in the company’s workshop. The tour will also speak with Mr. Shinji Yamaguchi of the Tokyo Head Office, who has designed seats for paracanoe, about the support system for athletes.

*Gishi: Prosthetics

<Companies Solving Issues with Advanced Disaster Prevention Technology>

1. Morita

Morita is Japan’s No. 1 fire truck manufacture, ranked third in fire truck sales globally and with approximately 90% domestic market share for ladder trucks. The company’s main overseas business is exporting ladder trucks, particularly to the rest of Asia.

In its over 110 years of history, Morita has developed a variety of unique fire trucks. Last year, they developed a ladder truck which people could get on while in a wheelchair, and a small off-road fire truck for use in disasters. Morita has also developed a new method to put out fires. Fire trucks with this NEA (Nitrogen Enriched Air) System create air with a high concentration of nitrogen using the air at the site of the fire, and spray this NEA to lower the oxygen level and prevents fires from spreading, creating an environment where fires cannot start. By controlling the concentration of the NEA being released, it is possible to maintain an oxygen concentration (12.5%) in which there is almost no effect on the human body in the short term, and fires cannot burn. This system can be used for fires where water is not easily available, or when secondary damage from water could be significant, such as computer rooms or electrical equipment.

.

The tour will visit Morita’s Sanda Factory (Hyogo Prefecture), which has an area of 57,000 square meters and produces over half the fire trucks used in Japan, and see a demonstration of the NEA System to learn about Morita’s system developed to extinguish fires using nitrogen. Outside the factory, there will be the opportunity to film and photograph a ladder truck which can reach up to the 10th floor of a building (30 meters) and a small off-road fire truck (TBD).

The tour will also be able to film and photograph fire trucks being made by hand from the observation hall with a view from above the production line.

*Since the tour will take place during a less busy time, there will likely be less fire trucks than in the picture here.

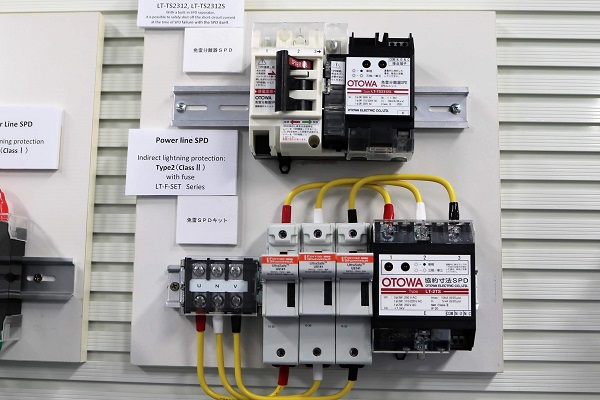

2. Otowa Electric Co., Ltd.

There is the risk that lightning strikes could cause severe damage to the electrical equipment that acts as the lifeline for various organizations, and so there is increasing recognition of the importance of a way to decrease the risks of damage from lightning strikes.

Since its establishment over 70 years ago, Otowa Electric has been a specialist in researching and developing lightning protection products, and is the No. 1 company in this area with 60% of the Japanese market share for distribution arresters and having supplied products for the Shinkansen and buildings such as Abeno Harukas. Distribution arresters are ceramic products attached to power poles and the like which can ground the extremely powerful excess voltage and current (lightning surge) running through the wires after a lightning strike. As opposed to lightning rods, which protect people and buildings from direct lightning strikes and are legally required in Japan to be installed on buildings over 20 meters tall, arresters protect electrical equipment from lightning surges entering buildings by nearby lightning strikes moving through power and communication lines.

Otowa Electric not only develops zinc oxide elements, the material that is at the heart of arresters, in house, it has also developed its own high-current testing facility that can reproduce most kinds of lightning from around the world, where it carries out lightning-related tests for clients. So far, they have carried out tests for Mitsubishi Heavy Industries when they were developing the MRJ passenger jet, as well as various other equipment manufacturers.

In addition to exporting zinc oxide elements to over a dozen countries worldwide, Otowa Electric’s international efforts include providing technological cooperation to Rwanda, a country with frequent lightning, through international students to Japan. The company has also started a project looking into overseas sales of arresters.

The tour will visit the Lightning Museum, where President Osamu Yoshida will explain the company’s products, as well as buildings and infrastructure that they have been involved in lightning protection for.

There will also be an opportunity to see the effects of a powerful current being run through wood at the high-current testing facility, one of the world’s most powerful with a maximum output of 220,000 amperes (no filming or photography allowed).

There will also be a demonstration of testing a lightning arrester by running high voltage through it (filming and photography is allowed).

3. Hitachi Zosen

Using the metalworking skills developed in its shipbuilding business, Hitachi Zosen has been involved in the construction of bridges and floodgates for over 100 years.

Hitachi Zosen decided to apply those skills to disaster prevention as well, and the land-based flap gates they started developing in 2009 have been used as countermeasures for water-based disasters including tsunami, storm surges, torrential rains, and flooding. These “neo RiSe” gates, an abbreviation of “No Energy, No Operation, Rising Seawall,” do not require power or manual operation, as the buoyancy and pressure of the water itself make them rise up to prevent the water from entering. Since they are just part of the ground normally, they do not interfere with anything, and can handle the weight of not just people, but even trucks and other vehicles. Over one hundred of these land-based gates for building and station entrances have already been installed throughout Japan, and efforts are underway to expand sales overseas as well. Iwate Prefecture has ordered the first of the version for seabed installation, and work is currently underway at the Sakai factory to deliver the product in 2020.

The tour will visit the Disaster Prevention Solutions Laboratory at the Sakai factory, and film and photograph a demonstration using approximately 90 tons of water. Land-based flap gates installed in representations of factory, office building, and train station entrances will rise up in response to the water and prevent it from entering.

Short video of the demonstration:https://youtu.be/shPPhiZIyCQ

[Tour Itinerary]

- Schedule

Day 1: March 19 (Tue)

|

7:30-10:05 |

Tokyo Station→Shin-Osaka Station (Nozomi 11) |

|

10:40-12:00 |

INTEX Osaka (summit venue), Sakishima Cosmo Tower (film/photograph INTEX exterior) |

|

13:50-15:20 |

Kongo Gumi |

|

16:05-17:35 |

Hitachi Zosen |

|

|

Stay at Sanda City (Hyogo) |

Day 2: March 20 (Wed)

|

8:30-10:30 |

Morita (Sanda Factory) |

|

11:30-13:00 |

Otowa Electric |

|

14:50-16:20 |

Kawamura Gishi |

|

16:50-18:20 |

Hardlock Industry |

|

19:20-21:53 |

Shin-Osaka Station→Tokyo Station (Nozomi 52) |

- Qualification: Bearer of Gaimusho Press Registration Card

- Cost: 15,000 Yen per person including transportation, accommodation and meals

*Information on payment and cancellation fee will be provided to participants.

- Participants: Limited to 10 applicants.

(Only one reporter or one photographer from each company, but two participants from each TV team will be acceptable.)

*If the number of applicants exceeds 10, an upper limit may be set on the number of participants from each country/region.

- FPCJ Contact: Ayako Sato (Tel: 03-3501-5251 | E-mail: sc@fpcjpn.or.jp)

- Remarks:

(1) This tour is organized by the Kansai Promotion Council for the 2019 G20 Osaka Summit Secretariat and planned and operated by the FPCJ.

(2) The schedule is subject to change without notice.

(3) This tour will require participants to bear part of the cost, but is not a profit-making venture.

(4) Neither the organizer nor FPCJ will be liable for any inconvenience, trouble or accidents that might occur during the tour.

(5) There may be some restrictions on photographing and filming at the tour sites. Please follow the instructions of the staff in charge.