実施日 : 2025年01月29日(水) - 30日(木)

Report: Fukushima Innovation Coast Framework Press Tour

投稿日 : 2025年02月25日

With nearly 14 years having passed since the Great East Japan Earthquake, a press tour sponsored by the Fukushima Innovation Coast Promotion Organization was held for foreign correspondents in Japan (planned/operated by the FPCJ).

The journalists visited Fukushima Prefecture’s coastal area (Hamadori) and were briefed on the framework by members of the Fukushima Innovation Coast Promotion Organization, followed by covering companies carrying out research and development under the Fukushima Innovation Coast Framework and visiting a local college of technology educating students so they could support the decommissioning of the Fukushima Daiichi Nuclear Power Station.

A total of ten journalists, from nine companies based out of eight countries, participated in this tour. The countries were France, Switzerland, Qatar, Vietnam, Brazil, Saudi Arabia/the US, and Japan.

*This press tour was sponsored by the Fukushima Innovation Coast Promotion Organization and planned/operated by the FPCJ.

*For details on the tour stops, please see the press tour announcement here.

[Day 1: Wednesday, January 29]

< Briefing by Fukushima Innovation Coast Promotion Organization/Fukushima Robot Test Field (Minamisoma) >

The journalists visited the Fukushima Robot Test Field, and heard from Mr. Wataru Kadowaki, vice general manager of the Interction Promotion Department of the Fukushima Innovation Coast Promotion Organization, about the Fukushima Innovation Coast Framework and its goals. Mr. Kadowaki explained how progress was being made on establishing an environment for research and support for businesses, and how it was contributing to creating jobs and training personnel.

The journalists asked about the funding source for Fukushima Innovation Coast Framework subsidies, whether overseas companies had used the Robot Test Field, what was particularly interesting about the research being carried out at the Robot Test Field that could not be seen elsewhere, and whether the existence of the Robot Test Field was contributing to stimulating the local community. Afterwards, the tour say the entire Robot Test Field from a rooftop.

< Zip Infrastructure, Inc. (Minamisoma) >

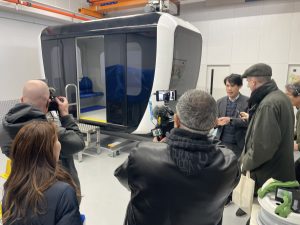

The tour visited Zip Infrastructure, Inc., which is developing a new transportation system called Zippar, a self-driven cable car system, to solve traffic congestion, which is becoming a severe issue in urban areas throughout the world. There, they heard from the company’s COO Mr. Mario Ian Carlos Ferido Rebonquin about Zippar, its unique features, and the future outlook for its use in Japan and overseas.

At the factory, the journalists were able to see the exterior of a Zippar cable car in development, as well as entering and seeing the interior as well, and they enthusiastically filmed and photographed it. The journalists asked why the decision was made to perform R&D in Fukushima, and whether there were plans for its use in residential areas as well. They also asked questions about plans to protect residents’ privacy, and measures for risks such as accidents.

< Aizawa Concrete Co. (Namie) >

The journalists visited the Fukushima RDM (Research/Development/Manufacturing) Center in Namie operated by Aizawa Concrete Co.

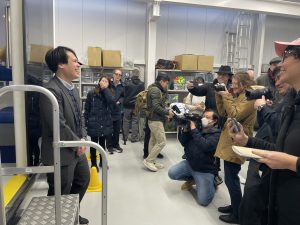

First, Aizawa Concrete executive officer Ms. Miki Ohashi explained the goal of establishing the Fukushima RDM Center and how it was being utilized, as well as explaining how the company, which promotes carbon neutrality, was the first in the world to succeed in mass production of its self-healing concrete, Basilisk.

Next, the journalists entered the concrete production building, and heard an explanation from the factory manager, Mr. Taichi Azuma, while seeing the concrete being made and enthusiastically taking photos and video of it.

Afterwards, the tour saw the 3D concrete printer the company uses in the R&D building. The tour heard from Mr. Hongtao Liu, the chief engineer of the Fukushima RDM Center, about how the Basilisk self-healing concrete takes advantage of bacterial reactions. He explained details of how the self-healing process works, and of concrete that can store heat or electricity that is currently being researched.

The journalists asked questions about the self-healing concrete, such as how big the cracks it could heal were. There were also many questions such as why the company, with its head office in Hokkaido, established the RDM Center in Fukushima; collaborations with overseas universities and companies; and the resilience to earthquakes of 3D printed concrete.

< AstroX, Inc. (Minamisoma) >

The final stop on the first day of the tour was AstroX, Inc., which is developing Rockoon (rocket + balloon) launch technology which uses a balloon to carry a rocket to the stratosphere, from where it is then air launched.

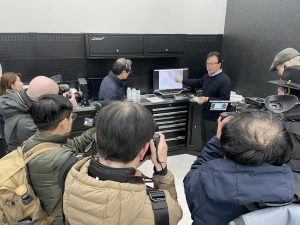

First, the tour heard from AstroX’s business development manager Mr. Kazuhiko Otani, who gave a briefing on the Rockoon launch method and its current state of development.

Next, the tour saw a replica of the rocket and its attitude control system, and had an online interview with AstroX’s CEO Mr. Shobu Oda. The journalists asked questions about measures to deal with space debris, the state of hiring in light of growing the company, why the decision was made to use the Rockoon method, and the level of interest in the space industry amongst youth.

[Day 2: Thursday, January 30]

< Kikuchi Seisakusho Co., Ltd. Minamisoma Factory (Minamisoma) >

The tour visited the Kikuchi Seisakusho Co., Ltd. Minamisoma Factory. Kikuchi Seisakusho supports startups as part of its business, and the tour covered one of the businesses it supported, Innophys Co., Ltd. Innophys is a university spinoff startup that applied artificial muscle technology to develop Muscle Suit exoskeletons which support laborers.

First, the tour heard from Mr. Naotaka Otogawa, a director of Kikuchi Seisakusho and representative director, president and CEO of Innophys, about Kikuchi Seisakusho and why it established the Minamisoma Factory, the relationship between Kikuchi Seisakusho and Innophys, how the Muscle Suit works, and examples of its use. Afterwards, the journalists had the opportunity to wear Muscle Suits for themselves and experience their effects.

Next, factory head Mr. Seiichi Sato guided the tour around the factory, where a variety of startups carry out R&D and production, and saw agricultural drones, service industry robots, and durability tests for the Muscle Suit.

The journalists asked questions about how many Muscle Suits had been sold, the ratio of sales in different industries such as manufacturing or nursing care, any concrete examples of their use by the JSDF or US military, and whether they were in use overseas.

< KiMiDoRi Co., Ltd. (Kawauchi) >

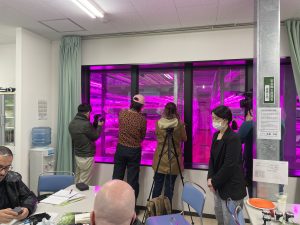

The tour then visited KiMiDoRi Co., Ltd. in Kawauchi. KiMiDoRi uses a system for hydroponic cultivation in a completely closed-off space to produce fresh leafy vegetables that can be eaten without washing.

The journalists heard from Mr. Kiyoteru Endo, vice-mayor of Kawauchi and KiMiDoRi’s president, about what led to founding the company and the unique characteristics of its facilities and products, and then saw the plant factory through the window along with an explanation from Ms. Maya Kaneko, head of the KiMiDoRi Production Development Department.

Later, the journalists had the opportunity to try fresh leaf lettuce grown in the factory, as well as a basil paste made from processing basil grown there. The journalists asked about differences in the taste between leaf lettuce grown in the facility and normal lettuce, as well as about the possibility of growing vegetables other than leafy vegetables, the relative productivity compared to growing vegetables in the open air, and where most of the produce was sent.

< National Institute of Technology, Fukushima College (Iwaki) >

The final stop on this press tour was the National Institute of Technology, Fukushima College in Iwaki. As a school located in Fukushima Prefecture, which experienced a nuclear disaster, the school focuses on educating students in the field of nuclear power. One initiative to that end is having students research and develops robots for decommissioning and participate in the Creative Robot Contest for Decommissioning that is held every year.

The journalists first heard from Professor Shigekazu Suzuki about initiatives to educate students in the field of nuclear power and about the curriculum. Next, the journalists heard from the students of the Fukushima Decommissioning Research Club about the unique characteristics of the robot developed for last year’s Creative Robot Contest for Decommissioning, and saw a demonstration of it in action.

The tour then visited the room where the students normally carried out R&D on their robots, and heard about their future plans after school and what led to them deciding to develop decommissioning robots.

The journalists asked questions about the possibility of actually using the robots developed by students for decommissioning, where they get their ideas for developing robots, their opinions on decommissioning, and what they thought about the decommissioning efforts currently ongoing at the Fukushima Daiichi Nuclear Power Plant.

◆Below are some of the reports based on this tour.

Vietnam Television (Vietnam)

" Thiết bị trợ lực giá rẻ dành cho người lao động tại Nhật Bản " (March 10, 2025)

Ouest France (France)

" Au Japon, l’innovation pour oublier la catastrophe de Fukushima " (February 18, 2025)

Record TV (Brazil)

" Fukushima: JR mostra como a tecnologia ajudou a recuperar região após acidente nuclear " (February 15, 2025)

Arab News Japan (Saudi Arabia)

" Area devastated by Fukushima earthquake re-emerges as tech development center " (January 30, 2025)