Date : June 13 - 14, 2019

Notice: G20 Osaka Summit 3rd Press Tour (Osaka, Nara)

post date : 2019.06.05

<Theme: Kansai, Supporting Japan’s Economy >

1. G20 Osaka Summit

2. Technology Creating the Future (SDGs, Life Sciences)

3. 2025 Osaka-Kansai Expo

On June 28 and 29, 2019, the G20 Summit will be held in Osaka. World leaders from advanced and emerging economies will meet to discuss how to achieve stable growth of the global economy, and topics including how to handle global issues such as the Sustainable Development Goals.

On June 28 and 29, 2019, the G20 Summit will be held in Osaka. World leaders from advanced and emerging economies will meet to discuss how to achieve stable growth of the global economy, and topics including how to handle global issues such as the Sustainable Development Goals.

Osaka and the Kansai region are home to a large number of manufacturers and companies involved in the life sciences. Using their unique technology, revolutionary products which can contribute to the SDGs are being made. These include “wearable robots” that allow anyone to perform manual labor regardless of age or strength, robotic furniture with the ability to change its height using advanced AI, and the world’s first high-capacity wireless charging system for electric vehicles. The technology of Osaka and the surrounding Kansai region is being used to create a sustainable society in which everyone can live happy and healthy lives, which is the theme of the 2025 Osaka-Kansai Expo.

This tour will go to Osaka and Nara, two weeks before the G20 Summit, and visit companies with outstanding technology in fields including life sciences and the environment. The tour will cover the power of Kansai in contributing to “Designing Future Society for Our Lives” with innovative technology and ideas.

[Tour Details]

<1. G20 Osaka Summit>

Kansai Promotion Council for the 2019 G20 Osaka Summit

The G20 Osaka Summit will be held at INTEX Osaka, an international exhibition center located on Sakishima, an artificial island in Osaka Bay. With 37 nations and organizations participating, it is expected that approximately 30,000 people will visit Osaka and the Kansai region for the summit, including heads of state, leaders of international organizations, government officials, foreign press, and staff. Locally, the Kansai Promotion Council for the 2019 G20 Osaka Summit, formed from business leaders, is playing a central role in the final preparations to welcome guests from around Japan and the world.

The secretariat of the Kansai Promotion Council for the 2019 G20 Osaka Summit, the sponsor of this tour, will speak about the preparations made in Osaka for the summit to be held two weeks after the tour. The Japan Association for the 2025 World Exposition, which will be running the 2025 Osaka-Kansai Expo, will also provide an explanation of the expo. The tour will then go to the Sakishima Cosmo Tower observation deck, located 252 meters above ground, where it will be possible to film and photograph INTEX Osaka and Yumeshima, the venue for the 2025 Expo in Osaka, Kansai.

<2. Technology Creating the Future (SDGs, Life Sciences) >

ATOUN Inc. (Nara)

Contributing to working style reform for manual labor with Powered Wear “wearable robots”

ATOUN is a robotics startup established in 2003. By developing “wearable robots” to decrease the physical burden on workers, the company has been working towards creating a “power-barrierless society” where people can work regardless of differences in strength due to factors such as age.

In 2018, ATOUN released the ATOUN MODEL Y, Powered Wear that supports the lower back worn like a backpack and turned on with a switch. Internalized sensors detect movements of the body core, and activate the motors at the waist to match the motion being made, reducing the burden on the lower back when lifting and lowering objects, or when bending at the waist. The MODEL Y is also waterproof and dustproof, so it can be used outdoors and in the rain.

The MODEL Y is being adopted mainly in construction and logistics, where packing and unpacking goods is central. From July 2018 when it was first released to the end of April 2019, approximately 300 units were sold. Japan Airlines purchased a total of 20 units, 10 units each for Haneda Airport and Narita Airport, and is using them for loading and unloading luggage and cargo. The MODEL Y is also being adopted more for agriculture and forestry, industries in which the average age of workers is increasing.

In May 2019, the company also revealed additional parts that can be attached to the MODEL Y for arm support. By adding arm support to the existing lower back support, work effectiveness is said to increase by up to 37.7% compared to when not using Powered Wear.

With the birthrate declining and the population aging, the workforce in Japan is decreasing, and working style reforms are necessary in the workplace. With Powered Wear decreases the burden on workers, helping to create a work environment in which anybody can actively work long-term.

After a briefing from ATOUN’s President Fujimoto on the creation of a Power-Barrierless Society using Powered Wear, the tour will have a chance to film and photograph demonstrations of Powered Wear such as the MODEL Y, as well as trying it on.

(Pictures provided by ATOUN Inc.)

I&C Co., Ltd. (Osaka)

Enabling barrier-free living with adjustable-height robotic furniture

I&C manufactures and sells robotic furniture using the latest technology, such as IoT and AI. Their products, such as kitchen and bathroom sinks, seem to just be well-designed normal furniture at first glance, but are raised and lowered with electric motors to adjust to an easy-to-use height for everyone, including children, seniors, or people in wheelchairs.

One of their products is a sink that can be raised or lowered with a single switch, making it convenient to use for people in wheelchairs or with other physical disabilities. Although washing hands and oral hygiene is important in nursing care, it can be a significant burden for caregivers. If the care recipients become able to brush their teeth themselves due to a sink that automatically adjusts height, it not only lessens the workload of the caregivers, it allows the person receiving care their independence, and enables them to live a more active life.

Until now, the interior design industry focused too much on design, with insufficient development of functionality, and the nursing and medical industries focused purely on functionality, ignoring design. I&C’s adjustable-height furniture has both design and functionality, pioneering a new market crossing over between the interior design and medical industries. Their products are used not only in hospitals and nursing care facilities, but also in private homes and luxury hotels.

Along with the increasing trend towards aging societies, interest in inclusive design has been growing around the world. In particular, in countries where nursing care for seniors is usually done at home, there is a demand for nursing goods that blend in with the interior. I&C’s “robotic furniture,” combining design and functionality, was selected for a national project by the Ministry of Foreign Affairs of Denmark. According to I&C President Yukio Sada, “We cannot compete with Western furniture manufacturers in design or brand recognition. Using Japan’s strength in the medical and nursing care industries, I would like to target the global market.”

The tour will hear from President Sada at the company’s showroom in Shinsaibashi, Osaka, and there will be an opportunity to film and photograph demonstrations of bathroom and kitchen counters having their height adjusted using switches or remote control.

(Right picture provided by I&C Co., Ltd.)

IWASAKI CO., LTD. (Osaka)

Applying detailed food sample techniques to food education and the medical industry

The food samples restaurants display in their windows can sometimes look even better than real food. IWASAKI was a pioneer of this industry, and the IWASAKI Group’s share of the Japanese domestic market is over 70%.

By applying its techniques used to manufacture food samples, IWASAKI also manufactures and sells food models used for nutrition education in hospitals and schools. These food models are handmade by veteran artisans, realistically replicating not only the appearance of the food, but also its size, weight, and texture. With this realism and the fact that they can be touched, when teaching about nutrition they can provide a concrete image that pictures or video could not, such as an appropriately sized meal or how many vegetables you should eat in a day. With the Food Education SAT System using food models with RFID tags, by placing the models on a special sensor it is possible to immediately display on a screen how many calories that meal has and the amount of nutrients it provides, as part of an experiential nutrition education system. By switching the food models around, it is possible to gain concrete experience in developing the ability to choose appropriate meals for yourself.

Food sample techniques are also being applied in the medical industry. One example is the Circuit training model for catheter insertions, developed via academic-industrial collaboration together with Kansai Medical University and Just Medical Corporation. Catheters are thin tubes inserted into blood vessels, for example, and used to treat medical issues from the inside, such as those involving the heart or blood vessels. Doctors have to rely on the sensation in their fingertips passed on from the catheter touching the blood vessels when passing it through, and it requires many years of experience. Having been consulted with by a doctor, IWASAKI successfully developed a model of the cardiac blood vessels using a one-piece silicone mold. This replicates the sensation of passing a catheter through a person’s blood vessels, which could not be achieved with glass or vinyl models. By simulating a sensation that doctors with little experience in using catheters could normally only experience in an actual surgery, this model will help prevent medical accidents. Many medical institutions have begun using the model, and Japanese catheter manufacturers have purchased it as well.

After listening to an explanation of how food sample techniques are being applied to nutrition education, there will be a demonstration of catheter insertion training. There will also be an opportunity to film and photograph artisans making food models by hand.

(Left and middle pictures provided by IWASAKI CO., LTD.)

DAIHEN Corporation (Osaka)

Increasing adoption of electric vehicles with wireless charging

The widespread adoption of electric vehicles (EV) is hoped to help with environmental issues such as climate change and atmospheric pollution, but issues remain such as extending their journey length and developing infrastructure for charging. Most existing EVs are intended to be used by plugging them in when parked at home, but if it became possible to provide simple high-powered charging anywhere, it would help increase adoption of EVs.

DAIHEN was established in 1919 and its 100th anniversary is coming up soon. In 2017, DAIHEN combined the power inverter and high-frequency power source technology they had cultivated to become the first in the world to commercialize a wireless charging system for EVs making it possible to charge rapidly at up to 11 kW. By simply parking the EV on top of the transmission coil installed in the surface of the parking space, charging begins automatically. As a method known as magnetic resonance, which can send large amounts of electricity a long distance, is used, there is a margin of error for parking the EV.

If installed at businesses such as convenience stores or restaurants, it would be possible to charge EVs while shopping, without having to deal with connecting cables, enabling more mobility without having to worry about running out of charge while out. If they were installed in roads, it could be possible to charge vehicles while they wait at stoplights or even while they are driving.

In 2018, DAIHEN also developed a wireless charging system for ultra-compact cars. Not only are they a good match for car sharing in tourist areas and remote islands, there is also hope ultra-compact cars will be a simple method of transportation in rural areas in an ageing society.

In March 2019, DAIHEN carried out the world’s first demonstration of a self-driving car using a wireless charging system. By combining the wireless charging system with a self-driving vehicle, the company hopes to support transportation from the train station to home in a next-generation mobility society.

After hearing an explanation of the wireless charging system, there will be an opportunity to film and photograph a demonstration of a self-driving vehicle parking at a charging point where the system is installed and beginning to charge automatically.

RYOHO FREEZE SYSTEMS CO., LTD. (Nara)

Reducing food waste loss with the latest freezing technology maintaining fresh-made taste

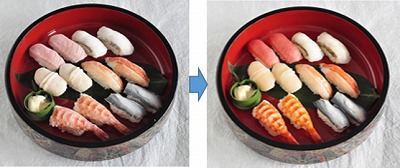

“Food which has been frozen doesn’t taste as good.” RYOHO FREEZE SYSTEMS, a manufacturer of refrigeration equipment, have solved this issue with their Proton freezing technology. It is possible to freeze food without damaging their freshness or taste, preserving the flavor of everything from raw foods, such as meat and fish, to sushi and cakes made with fresh cream.

The reason that taste and texture worsens upon freezing is that the water content in food forms large ice crystals during the freezing process, damaging cells and leading to a loss of flavor and nutrients when thawed. With Proton freezing, a combination of magnetic flux, electromagnetic waves, and cold air are used to prevent ice crystals from damaging cells, ensuring the same taste and texture after thawing. When thawing, there is less than one-third of the normal amount of water content loss.

With this freezing technology that preserves the freshness and taste of food products, food waste loss has been reduced, and it has become possible to make safe food products without using additives. Being able to prepare in advance products for which demand is concentrated in a limited period is also a significant benefit for workplaces dealing with labor shortages. For example, Japanese traditional osechi food eaten at New Year’s previously had to be made all at once at the end of the year, but with Proton freezing it would be possible to begin preparing it in the summer or fall.

It is possible to experience the future of food logistics using this latest freezing technology at the Proton Dining restaurant located on the first floor of RYOHO FREEZE SYSTEMS’ head office. A majority of the menu at this restaurant, which serves authentic full-course French meals, is prepared at the company’s factory in Okinawa. Fresh ingredients from around Japan are sent to this factory using Proton freezing. At the restaurant, food is thawed for each order, with only some plating necessary, making it possible to quickly serve meals with only a small staff, and preventing waste loss.

There is also hope that Proton freezing can be applied to the field of regenerative medicine. Even when using ultra-low temperature medical freezers, the survival rate of cells is only around 40%, but using Proton freezing a survival rate of over 80% is possible.

After hearing about applications for Proton freezing technology, the tour will see Proton frozen food being prepared at Proton Dining and be able to try it.

(Left and middle pictures provided by RYOHO FREEZE SYSTEMS.CO., LTD.)

<3. 2025 Osaka-Kansai Expo>

Taiyo Kogyo Corporation (Osaka)

A leading company in membrane structures since the 1970 Expo in Osaka

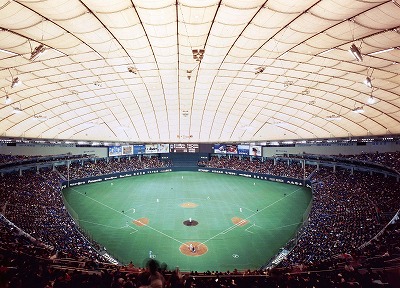

Taiyo Kogyo is a leading company in membrane structures. The company has made membrane roofs for airports, convention centers, and sports facilities around the world, including the Tokyo Dome and Olympic stadiums, and has one of the largest market shares in the industry worldwide. At Al-Masjid an-Nabawi (The Prophet’s Mosque), the second-holiest site in Islam, there are 250 umbrellas which cover 25.5 square meters which were made by Taiyo Kogyo, providing pilgrims from around the world with shade from the sun.

Taiyo Kogyo had been an established tent manufacturer, and the impetus for it becoming a leading company in membrane structures was the 1970 World Expo in its hometown of Osaka. The company made around 90% of the canvas pavilions of various sizes that were used at the Expo. In particular, the US pavilion amazed the world as the first massive membrane roof to be supported by air pressure alone, without any pillars. Manufacturing a single membrane of around 10,000 square meters was unprecedented, and it took three days just to fold the finished product at the factory. It was so large, they had to make an opening in one of the factory’s walls to transport it to the Expo grounds.

With the 1970 Expo, tents were no longer considered as something to be used just to avoid the sun, and became recognized around the world as a new type of structure. With the development of new materials, Taiyo Kogyo’s membrane structures became used not only for temporary expos and events, but also as permanent structures for sports stadiums, stations, and airports. The first instance of this in Japan was INTEX Osaka, the venue for the G20 Osaka Summit in June (construction of it was completed in 1984). In 1988, Tokyo Dome was also completed, a major point in history for Japanese membrane structures.

Since membranes are light, sturdy, and allow light to pass through, they are an excellent material for earthquake resistance and saving energy, and are being used more frequently. In the area of environmental conservation, Taiyo Kogyo was the first in the world to develop an undersea membrane, used to prevent ocean pollution when reclaiming land. For Expo 2005, held in Aichi, the tent providing shade on the main street was made using kenaf, and after the Expo was recycled into paper. Taiyo Kogyo is carrying out new research and development in preparation for the 2025 Osaka-Kansai Expo.

The tour will visit Taiyo Kogyo’s Hirakata factory, where the roof for the 1970 Expo US pavilion and the umbrella’s for Medina were made, and be able to film and photograph tents being made by hand in a location similar to a gymnasium.

(Left and middle pictures provided by Taiyo Kogyo Corporation)

WAKAZO

“The future will be made by the youth. We will make the Expo together with youth from around the world.”

Functionally the last presentation for the bid to host Expo 2025 in Osaka/Kansai was at the General Assembly of the Bureau International des Expositions held in June 2018 in Paris. Joining Nobel Prize winner and Kyoto University Professor Shinya Yamanaka on the stage was Ayako Kawatake, head of the student group WAKAZO based out of Kansai (and a fifth-year student in medicine at Kyoto University at the time). Ms. Kawatake contributed to the successful bid by saying, “Bet on the youth for a bright future and hold the Expo in Osaka.”

WAKAZO’s parent organization was the “inochi Gakusei Project,” a group of Kansai medical students with the goal of solving healthcare issues such as suicide and dementia through the efforts of youths. Learning in the fall of 2016 that a bid was being made for the Expo, and that the average age of the members of the committee involved was over 60, the group felt that youths would have to participate in order to make the Expo a success, and wrote “100 Youth Recommendations for the 2025 Osaka Expo Bid.” Then, sympathizing with the theme of the Expo of spreading the message from Osaka of a bright future society where everyone around the world can live an energetic and healthy life, WAKAZO was founded in December 2016 to help support the Osaka-Kansai Expo independently. There are around 30 main members, from high school students to graduate students.

WAKAZO’s slogan is “Half the population of the world is 30 or under. WAKAZO (youths) have the starring role.” The goal of the group is to work towards solving common issues of humanity, starting with the SDGs, by holding an Expo where every youth can be a star, as they will be supporting the world in the future. The group has used its homepage, as well as members travelling the world as backpackers, to gather information on the awareness youths have of issues and their ideas for solutions, finding others to work together in solving issues. For the 2025 Osaka-Kansai Expo, they are trying to make their planned WAKASO pavilion happen, where they will present the ideas they have gathered and make it into a place for experimentation with youths as the focus.

The tour will hear from some of the members who were most active in lobbying for the bid about their thoughts on the World Expo.

[Tour Itinerary]

1. Schedule

*The schedule is not yet finalized, and may change without notice.

<Day 1: June 13 (Thu)>

7:10-9:37 Tokyo Station- Shin-Osaka Station (Nozomi #9)

10:15-11: 30 DAIHEN Corporation

12:00-12:45 Lunch

13:00-14:10 I&C Co., Ltd

14:45-16:15 IWASAKI CO., LTD.

17:00-18:00 Kansai Promotion Council for the 2019 G20 Osaka Summit

19:30 Arrive at hotel

<Day 2: June 14 (Fri)>

8:20 Leave hotel

9:00-10:30 ATOUN Inc.

11:00-13:00 RYOHO FREEZE SYSTEMS.CO., LTD. (lunch included)

14:00-15:40 Taiyo Kogyo Corporation (Hirakata Factory)

16:30-17:30 WAKAZO

18:53-21:23 Shin-Osaka Station – Tokyo Station (Nozomi #252)

2. Qualification: Bearer of Gaimusho Press Registration Card

3. Cost: 15,000 Yen per person including transportation, accommodation and meals

*Information on payment and cancellation fee will be provided to participants.

4. Participants: Limited to 10 applicants.

(Only one reporter or one photographer from each company, but two participants from each TV team will be acceptable.)

*If the number of applicants exceeds 10, an upper limit may be set on the number of participants from each country/region.

5. FPCJ Contact: Sugawara (Mr.), Hamada (Ms.)

6. Remarks:

(1) This tour is organized by the Kansai Promotion Council for the 2019 G20 Osaka Summit and planned and operated by the FPCJ.

(2) The schedule is subject to change without notice.

(3) This tour will require participants to bear part of the cost, but is not a profit-making venture.

(4) Neither the organizer nor FPCJ will be liable for any inconvenience, trouble or accidents that might occur during the tour.

(5) There may be some restrictions on photographing and filming at the tour sites. Please follow the instructions of the staff in charge.