実施日 : 2015年02月12日(木) - 13日(金)

Notice: Kyoto Press Tour “Lessons of the Thousand-Year Capital”

投稿日 : 2015年01月26日

- The frontline for preservation of cultural properties -

- Traditional craftsmen cultivating overseas markets -

- Kyoto entrepreneurs keeping the craftsman’s spirit alive -

--- The frontline for preservation of cultural properties ---

Kyoto is a city with over 1000 years of history.  There are 208 National Treasures in the city, and 17 shrines, temples and a castle in the city and its vicinity are listed as UNESCO World Heritage Sites. With the vast numbers of cultural properties in Kyoto, there are people striving to ensure they remain available to later generations. These people range from an artist using his years of experience and knowledge to replicate the 400-year-old brushstrokes of wall paintings in Nijo Castle, to a world leader in digital archiving technology using the latest technology to develop a specialized scanner for digital preservation of cultural properties. As the frontline for the preservation of cultural properties, Kyoto cultivates both highly-skilled artisans and cutting-edge technology.

There are 208 National Treasures in the city, and 17 shrines, temples and a castle in the city and its vicinity are listed as UNESCO World Heritage Sites. With the vast numbers of cultural properties in Kyoto, there are people striving to ensure they remain available to later generations. These people range from an artist using his years of experience and knowledge to replicate the 400-year-old brushstrokes of wall paintings in Nijo Castle, to a world leader in digital archiving technology using the latest technology to develop a specialized scanner for digital preservation of cultural properties. As the frontline for the preservation of cultural properties, Kyoto cultivates both highly-skilled artisans and cutting-edge technology.

--- Traditional craftsmen cultivating overseas markets ---

There are a variety of traditional industries in Kyoto, such as kimono makers, in which techniques have been passed down through the generations. However, with the westernization of lifestyle in Japan in recent years, their markets have shrunk and the number of craftsmen has decreased. In attempts to overcome this dire situation, a pattern engraver has expanded beyond kimonos, and a bamboo dealer has developed fireproof bamboo material and expanded into foreign markets.

--- Kyoto entrepreneurs keeping the craftsman’s spirit alive ---

The monozukuri spirit has always been strong within Kyoto, and is still present in the manufacturing industry today, with many Kyoto companies leaders in the global market. Kyoto is well-known for having many precision equipment and electronics manufacturers. This is why a Kyoto venture company has developed the first sports electric vehicle (EV) in Japan. A unique feature is its use of technology and parts made in Kyoto.

------------------------------------------------------------------------------------------

This press tour visit Kyoto City. In addition to interviewing the mayor, it will:

-Meet a Japanese-style artist who is involved in replicating 400-year-old wall paintings in Nijo Castle, and a world-renowned expert in digital archiving technology who has used advanced technology to develop a special scanner for cultural properties.

-As an example of craftsmen in traditional industries developing foreign markets in response to decreasing domestic demand, interview the fourth-generation heir to a bamboo dealer who has developed the first fireproof bamboo in Japan and is actively promoting sales to the European interior design market, and a master engraver of paper patterns used in dyeing kimono fabric who has applied his techniques to develop new products such as iPad cases.

-Visit a Kyoto-based venture company that has inherited the monozukuri spirit and gathered the technology of different Kyoto parts manufactures in order to develop the first electronic sports car in Japan.

------------------------------------------------------------------------------------------

※This press tour is sponsored by Kyoto City, with planning and operation by the FPCJ.

[Tour Details]

1. Interview with Kyoto Mayor Daisaku Kadokawa

- Beauty and wisdom born of 1000 years of history -

http://www.city.kyoto.jp/koho/eng/mayor/welcome.html

Kyoto is a city with over 1000 years of history. There are 208 National Treasures in the city, and 17 shrines, temples and a castle in the city and its vicinity are listed as UNESCO World Heritage Sites. In order to preserve and pass on Nijo Castle, a World Heritage Site and National Treasure that the city manages, there is currently a large scale restoration project underway on the castle, which was built in 1603 by Ieyasu Tokugawa.

With a wide variety of historical attractions including cultural properties, Kyoto is one of Japan’s primary tourist destinations. In 2014, there were 51.62 million tourists, 1.13 million foreigners staying overnight, and tourism spending of 700.2 billion yen, all of which are new records. In a 2014 reader survey by Travel + Leisure magazine, a major American travel magazine with a monthly circulation of one million, the most popular tourist destination in the world was Kyoto.

In addition to the tourism industry, Kyoto is also home to many traditional industries that have developed over its long history and exist to this day. The city provides support for them to expand into foreign markets, and for planning events such as craftsmen participating in European exhibitions and performing collaborations with designers in Paris.

◆There will be opportunities to hear about a variety of city initiatives from the mayor.

----- The frontline for preservation of cultural properties -----

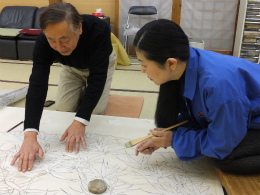

2. Nijo Castle, Wall Painting Reproduction, Japanese-style Painter Toshihide Tanii (65)

- Largest-scale reproduction project in Japan. 400-year-old beauty being revived by today’s artists -

http://www.city.kyoto.jp/bunshi/nijojo/english/index.html

http://www.kawamo-art.com/nijo-castle/

Nijo Castle was built in the Edo Period, and is designated as a  UNESCO World Heritage Site. The Ninomaru Palace inside the castle has over 1000 wall paintings from 1626 by the Kano School, which have been designated by the national government as Important Cultural Properties. But with the collective damage of 400 years, preservation is necessary as soon as possible. Therefore, Kyoto City has been making reproductions since 1972. When reproduction of a screen is completed, it is displayed instead of the original, and the original is kept in storage at controlled temperature and moisture levels. Modern Japanese artists perform the reproductions. They carefully observe and analyze the originals and faithfully replicate the techniques of 400 years ago. Mr. Toshihide Tanii (65), who has been involved in the reproductions for 47 years, said “It is difficult to bring across the skills of the original artists through reproductions, but I can’t be sloppy. I want to pass on the feelings of the artists at the time and communicate them to later generations.”

UNESCO World Heritage Site. The Ninomaru Palace inside the castle has over 1000 wall paintings from 1626 by the Kano School, which have been designated by the national government as Important Cultural Properties. But with the collective damage of 400 years, preservation is necessary as soon as possible. Therefore, Kyoto City has been making reproductions since 1972. When reproduction of a screen is completed, it is displayed instead of the original, and the original is kept in storage at controlled temperature and moisture levels. Modern Japanese artists perform the reproductions. They carefully observe and analyze the originals and faithfully replicate the techniques of 400 years ago. Mr. Toshihide Tanii (65), who has been involved in the reproductions for 47 years, said “It is difficult to bring across the skills of the original artists through reproductions, but I can’t be sloppy. I want to pass on the feelings of the artists at the time and communicate them to later generations.”

◆The tour will visit Ninomaru Palace in Nijo Castle, and see both originals and reproductions of wall paintings. The tour will then see where the wall paintings are being reproduced, and have an opportunity to speak with the artists.

◎Note: Photography will not be permitted inside Ninomaru Palace. Instead, in the reproduction workroom, there will be both original and reproduced wall paintings and you can photograph there.

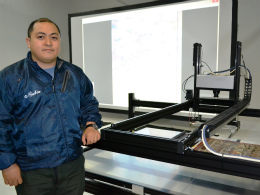

3. Kyoto University, Graduate School of Engineering, Advanced Imagining Technology,

Professor Ari Ide (61)

- Making Kyoto the world headquarters for digitally preserving cultural properties with advanced technology -

http://www.kyotoheritage.jp/en/index.html

http://research.kyoto-u.ac.jp/documentary/ide/01/

Professor Ide came to Japan from Iran in 1972 to study at Kyoto University. Originally he was involved in developing hardware and software to digitally capture the elements of brain cells. After working on one project, he became interested in digital archiving for the preservation of cultural properties, and is now one of the leading authorities in the field. Working together with manufacturers, he succeeded in developing an ultra-high resolution 2D image acquisition scanner specifically for cultural properties. Since it scans cultural properties as images at high resolution and high color fidelity, it not only ensures semi-permanent preservation, but is also useful in analyzing materials, surface geometry and color information, and at estimating pigments and painting techniques used. According to Professor Ide, “Cultural properties have three enemies. War, poverty, and ignorance. The current situation in Syria is grim. When you consider that over 1000 cultural properties were lost in the Great East Japan Earthquake, disasters are also a major enemy.” Currently, he is participating in international projects in China, Hong Kong, South Korea, Spain (Museo del Prado), and Egypt, as well as helping train people to preserve cultural properties worldwide (with international bases in China, Hong Kong, South Korea, Australia, the UK, Italy and the USA). “Japan leads the world in digital archiving technology. Since Kyoto has a particularly large number of cultural properties, it could become a global center.” The professor has been involved in various digital archiving projects such as the Kannon-do at Ninna-ji Temple and the wall paintings at Nijo Castle. Recently, this technology has been the focus of renewed attention due to it now being able to develop high-resolution images for 8K displays.

Originally he was involved in developing hardware and software to digitally capture the elements of brain cells. After working on one project, he became interested in digital archiving for the preservation of cultural properties, and is now one of the leading authorities in the field. Working together with manufacturers, he succeeded in developing an ultra-high resolution 2D image acquisition scanner specifically for cultural properties. Since it scans cultural properties as images at high resolution and high color fidelity, it not only ensures semi-permanent preservation, but is also useful in analyzing materials, surface geometry and color information, and at estimating pigments and painting techniques used. According to Professor Ide, “Cultural properties have three enemies. War, poverty, and ignorance. The current situation in Syria is grim. When you consider that over 1000 cultural properties were lost in the Great East Japan Earthquake, disasters are also a major enemy.” Currently, he is participating in international projects in China, Hong Kong, South Korea, Spain (Museo del Prado), and Egypt, as well as helping train people to preserve cultural properties worldwide (with international bases in China, Hong Kong, South Korea, Australia, the UK, Italy and the USA). “Japan leads the world in digital archiving technology. Since Kyoto has a particularly large number of cultural properties, it could become a global center.” The professor has been involved in various digital archiving projects such as the Kannon-do at Ninna-ji Temple and the wall paintings at Nijo Castle. Recently, this technology has been the focus of renewed attention due to it now being able to develop high-resolution images for 8K displays.

◆The tour will hear from Professor Ide and see a demonstration of the scanner.

----- Traditional craftsmen cultivating overseas markets -----

4. Yokoyama Bamboo Products Co., Ltd., Fourth-generation Owner (Executive Director) Mr. Yuki Yokoyama (35)

- Plan to grow the European interior design market for bamboo material. Development of the world’s first fireproof bamboo material. -

http://yokotake.net/en/index.html

http://www.yokotake.co.jp/e_pages/products.htm

Yokoyama Bamboo Products was established in 1919, and has provided bamboo for the Kyoto State Guest House and bamboo fences for the Urasenke tea ceremony school, as well as the bamboo for the interior of the store in Kabuki-za (designed by Dr. Kengo Kuma). Kyoto has historically been known for its excellent bamboo processing, and so there are many craftsmen specializing in bamboo there. However, as life in Japan has become westernized, domestic demand for bamboo has decreased, and many companies are shutting down. The industry as a whole is shrinking. “At this rate, the industry will keep shrinking and so no young people will enter it,” says the fourth-generation successor to Yokoyama Bamboo Products, Mr. Yuki Yokoyama (35). In response to this situation, he is attempting to create new demand by marketing to the European interior design market. The company entered a contract with an agent in London and began exports in 2012, and participated in an exhibition in France this year. Mr. Yokoyama says he has started to see results from doing business overseas. “I would like to increase overseas sales and make this into an industry which appeals to young people.” Based on the philosophy that monozukuri techniques (craftsman’s skills) will decline if the next generation isn’t trained, the company actively tries to hire young employees. Half of its 12 employees are in their 20s and 30s.

for the Kyoto State Guest House and bamboo fences for the Urasenke tea ceremony school, as well as the bamboo for the interior of the store in Kabuki-za (designed by Dr. Kengo Kuma). Kyoto has historically been known for its excellent bamboo processing, and so there are many craftsmen specializing in bamboo there. However, as life in Japan has become westernized, domestic demand for bamboo has decreased, and many companies are shutting down. The industry as a whole is shrinking. “At this rate, the industry will keep shrinking and so no young people will enter it,” says the fourth-generation successor to Yokoyama Bamboo Products, Mr. Yuki Yokoyama (35). In response to this situation, he is attempting to create new demand by marketing to the European interior design market. The company entered a contract with an agent in London and began exports in 2012, and participated in an exhibition in France this year. Mr. Yokoyama says he has started to see results from doing business overseas. “I would like to increase overseas sales and make this into an industry which appeals to young people.” Based on the philosophy that monozukuri techniques (craftsman’s skills) will decline if the next generation isn’t trained, the company actively tries to hire young employees. Half of its 12 employees are in their 20s and 30s.

Mr. Yokoyama also succeeded in developing the first fireproof bamboo material in the world. Current Japanese laws (the Fire Service Act) only allow for limited use of bamboo as construction materials in commercial buildings, such as inns and restaurants. These regulations lead to cases where bamboo is not allowed even if the business wants to use it, or where they use wallpaper with bamboo patterns printed on it instead of authentic bamboo. To deal with this, Mr. Yokoyama spent five years developing a new bamboo material that retains its natural appearance after being chemically treated. In January 2014, the Fire and Disaster Management Agency gave permission for its use. It is hoped that it will help increase demand for the use of authentic bamboo.

Mr. Yokoyama also succeeded in developing the first fireproof bamboo material in the world. Current Japanese laws (the Fire Service Act) only allow for limited use of bamboo as construction materials in commercial buildings, such as inns and restaurants. These regulations lead to cases where bamboo is not allowed even if the business wants to use it, or where they use wallpaper with bamboo patterns printed on it instead of authentic bamboo. To deal with this, Mr. Yokoyama spent five years developing a new bamboo material that retains its natural appearance after being chemically treated. In January 2014, the Fire and Disaster Management Agency gave permission for its use. It is hoped that it will help increase demand for the use of authentic bamboo.

◆The tour will hear from Mr. Yokoyama about why his company entered the international market and his future plans, and observe craftsmen working with bamboo.

5. Nishimura Yuzen Chokoku, Mr. Takeshi Nishimura (61)

- Paving the way for the next generation. Expanding from kimonos to new products -

http://www.nishimura-yuzen-chokoku.com/en/index.php

Nishimura Yuzen Chokoku was established in 1934. It is a specialist in  yuzen chokoku, the art of engraving paper for dyeing in the kyo-yuzen style created in Kyoto. These paper patterns are used to make a variety of patterns on the fabric for kimonos. Second-generation owner Mr. Takeshi Nishimura is a veteran with over 40 years of experience. When dyeing, up to 400 or 500 patterns can be used for a single kimono, but with the production of kimonos decreasing in recent years, the amount of work and number of craftsmen has also decreased drastically.

yuzen chokoku, the art of engraving paper for dyeing in the kyo-yuzen style created in Kyoto. These paper patterns are used to make a variety of patterns on the fabric for kimonos. Second-generation owner Mr. Takeshi Nishimura is a veteran with over 40 years of experience. When dyeing, up to 400 or 500 patterns can be used for a single kimono, but with the production of kimonos decreasing in recent years, the amount of work and number of craftsmen has also decreased drastically. Mr. Nishimura, believing that “Techniques that aren’t useful won’t be passed on” and “People won’t learn techniques if they can’t make a living from them,” applied the engraving techniques to new materials such as leather, and developed new products such as iPad cases. His design where the light of the LCD screen shines through engravings was well received, and was picked up for sale by a major department store in Tokyo. With support from Kyoto City, he has also participated in exhibitions overseas, and is currently collaborating on products with a designer in Paris. “When I was working on kimonos, I was a subcontractor and had almost no contact with customers, but now my techniques are being directly appreciated by customers. I’m glad to have done the work I have. I hope there will be people who want to carry on my techniques.”

Mr. Nishimura, believing that “Techniques that aren’t useful won’t be passed on” and “People won’t learn techniques if they can’t make a living from them,” applied the engraving techniques to new materials such as leather, and developed new products such as iPad cases. His design where the light of the LCD screen shines through engravings was well received, and was picked up for sale by a major department store in Tokyo. With support from Kyoto City, he has also participated in exhibitions overseas, and is currently collaborating on products with a designer in Paris. “When I was working on kimonos, I was a subcontractor and had almost no contact with customers, but now my techniques are being directly appreciated by customers. I’m glad to have done the work I have. I hope there will be people who want to carry on my techniques.”

◆The tour will hear from Mr. Nishimura about engraving techniques and developing new projects, as well as seeing the engraving process and products he has made.

----- Kyoto entrepreneurs keeping the craftsman’s spirit alive -----

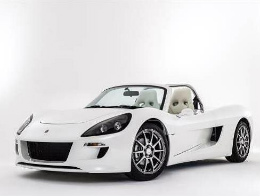

6. GLM.Co.,Ltd., President Hiroyasu Koma (37)

- A venture company making the first electric (EV) sports car in Japan, bringing together Kyoto technology and parts -

GLM.Co.,Ltd. is a Kyoto-based venture company developing and  selling Japan’s first mass-produced electric sports car. With his research into electric vehicles at Kyoto University as a jumping off point, President Koma started the company in 2010 at the age of 32. One of the main features of their car is how it largely uses parts and technology from Kyoto companies. The battery, charger and power relay all use parts from various manufacturers in Kyoto. Kyoto is famous for its precision equipment and electronics manufacturers, many of them leaders in the global market. The reason so many companies are gathered in Kyoto is said to be due to the traditional monozukuri (craftsmanship) spirit being maintained there to this day.

selling Japan’s first mass-produced electric sports car. With his research into electric vehicles at Kyoto University as a jumping off point, President Koma started the company in 2010 at the age of 32. One of the main features of their car is how it largely uses parts and technology from Kyoto companies. The battery, charger and power relay all use parts from various manufacturers in Kyoto. Kyoto is famous for its precision equipment and electronics manufacturers, many of them leaders in the global market. The reason so many companies are gathered in Kyoto is said to be due to the traditional monozukuri (craftsmanship) spirit being maintained there to this day.

Initial acceleration is a key feature of sports cars, and this is an area electric vehicles excel at. Even if it is not possible to do a large production run as a venture company, with sports cars the rarity will just make them more valuable. These points are what made Mr. Koma decide there was potential in a venture company producing an electric sports car. In July 2014, GLM’s Tommykaira ZZ was the first mass produced electric sports car in Japan to be certified by the Ministry of Land, Infrastructure, Transport, and Tourism. This made it possible for these cars to get license plates and be driven on public roads in Japan. The cars cost 8 million yen (tax excluded). It was a limited production run of 99 vehicles, but preorders exceeded the limited number of cars produced. Sales and deliveries are currently underway. According to Mr. Koma, “Making an EV in the Environmental Model City of Kyoto is a message in itself.”

Initial acceleration is a key feature of sports cars, and this is an area electric vehicles excel at. Even if it is not possible to do a large production run as a venture company, with sports cars the rarity will just make them more valuable. These points are what made Mr. Koma decide there was potential in a venture company producing an electric sports car. In July 2014, GLM’s Tommykaira ZZ was the first mass produced electric sports car in Japan to be certified by the Ministry of Land, Infrastructure, Transport, and Tourism. This made it possible for these cars to get license plates and be driven on public roads in Japan. The cars cost 8 million yen (tax excluded). It was a limited production run of 99 vehicles, but preorders exceeded the limited number of cars produced. Sales and deliveries are currently underway. According to Mr. Koma, “Making an EV in the Environmental Model City of Kyoto is a message in itself.”

◆President Koma will describe the history of the car’s development, and what Kyoto technology is being used in it. There will also be a demonstration of and opportunity to take a test ride in the EV sports car.

[Itinerary]

<Day 1: February 12 (Thursday)>

8:00 Meet at Tokyo Station

8:13-10:31 Tokyo to Kyoto (Shinkansen)

11:00-12:30 Nijo Castle

13:00-14:00 Lunch

14:30-15:45 Yokoyama Bamboo Products, Executive Director Yuki Yokoyama

16:15-17:30 Nishimura Yuzen Chokoku, Mr. Takeshi Nishimura

18:30-20:00 Supper

<Day 2: February 13 (Friday)>

8:30- Leave hotel

9:15-11:15 Kyoto University, Graduate School of Engineering, Advanced Imagining

Technology, Professor Ari Ide

11:15-12:15 Travelling

12:15-13:00 Lunch

13:00-14:45 GLM Co., Ltd.

14:45-15:45 Travelling

16:00-17:00 Interview with Mayor Daisaku Kadokawa

18:29-20:50 Kyoto to Tokyo (Shinkansen)

2. Qualification: Bearer of Gaimusho Press Registration Card

3. Cost: 10,000 yen per person including transportation, meals and accommodation

* FPCJ will later inform the participants of methods for payment, cancellation fee etc.

4. Participants: Limited to 10 applicants.

(Only one reporter and one photographer from each company, but two participants from each TV team will be acceptable.)

5. FPCJ Contact: Ms. Chika Yoshida (Tel: 03-3501-3405)

6. Remarks:

(1) There may be some restrictions on photographing and filming at the tour sites. Please follow the instructions of the officials on duty.

(2) FPCJ and Kyoto City will not be liable for any inconvenience, trouble or accident that might occur in the course of the tour.

(3) Participants will have to cover a portion of the cost for this press tour, but it is not a profit-making enterprise.