OVERVIEW

- Tour Dates

- Thursday, November 27–Friday, November 28, 2025

- Place

- Shiga Prefecture

- Participants

- Limited to 10 participants.(Only one reporter or one photographer from each company, but two participants from each TV team will be acceptable.)

- Topics

- 1. The Lifestyles and Industries Nurtured by Lake Biwa, the Largest Lake in Japan

2. SMEs Nurtured by Mt. Ibuki, a Treasure Trove of Medicinal Plants

3. Production with Traditional Methods of Silk Thread and Silk Strings for Instruments

Purpose of Tour

Lake Biwa has an area of approximately 670 square kilometers and a shore length of approximately 235 kilometers, making it the largest lake in Japan.

Shiga Prefecture, home to Lake Biwa, has a number of unique industries taking advantage of the lake’s resources, such as its ample water and ecosystem. Located in a key position for travel from east to west, with both the Tokaido and Nakasendo highways of the Edo period passing through, Shiga Prefecture has also long been a center for commerce.

Pearls are cultured in Lake Biwa using freshwater mussels (Hyriopsis schlegelii). Funazushi, made by fermenting rice and an endemic species of crucian carp, is a well-known food representing the area. Near Lake Biwa, Mt. Ibuki has long been a source of medicinal plants, and so the production of moxa, used in Eastern medicine, is also prevalent in the area. This region is also one of the few in Japan where silk continues to be produced by hand, with that silk being used to make strings for traditional instruments such as koto. These strings are popular among professional musicians not only in Japan, but in China and South Korea as well.

Despite having supported people’s lives over the ages, during the postwar economic miracle (the 1950s to 1970s) its water quality worsened for a time due to industrial wastewater. However, grassroots efforts by locals led to the water quality improving again, and a variety of conservation initiatives are being continued to this day.

◆This press tour will cover the unique SMEs and lifestyles which developed in the environment around Lake Biwa. In addition to industries using resources specific to the area, the tour will also look at people’s efforts to continue to pass on those resources and industries through the generations.

Tour Details

The Lifestyles and Industries Nurtured by Lake Biwa, the Largest Lake in Japan

1. People’s Lives Alongside Lake Biwa, and the History of Conservation of Lake Biwa

(1) Omi Hachiman Tourism Association (Omi Hachiman): The Lifestyles of People Together with Lake Biwa

—The history of Omi merchants, who originated from a town with a waterway connected to Lake Biwa

-

[Photo courtesy of Omi Hachiman Tourism Association]

In Omi Hachiman, Shiga, there is a 4.75 kilometer long canal called Hachiman-bori that is connected to Lake Biwa.

Toyotomi Hidetsugu, who ruled this area during the Warring States period, built the Mt. Hachiman castle in 1585, connecting the castle’s moat and Lake Biwa with a canal so boats traveling on the lake could pass through the town. This led to more people, products, and information gathering in the town, and helped promote economic activity there.

By around the 18th century, Omi merchants were traveling around the country doing business. They carried out their business under the philosophy of the “three goods,” “good for the seller, the buyer, and society,” similar to the modern day SDGs. This spirit has been passed down through the ages, and has influenced numerous leading companies in modern Japan.

The canal, which long played a role in transportation and daily life in the town, grew to be forgotten by the residents and become nothing more than an unnecessary source of pollution when lifestyles began changing in the late 1950s. Despite a plan to fill in the canal even being suggested at one point, thanks to conservation and recovery efforts by local youths it regained its former beauty, and is now a sight beloved by many tourists.

◆The tour will visit the Omi Hachiman Municipal Museum (the former residence of the Nishikawa Clan) and hear from its director, Mr. Masaharu Maesaka, about the Omi merchants and the history of Omi Hachiman’s development, as well as learning about background information relevant to covering SMEs in Shiga Prefecture. Afterwards, the tour will visit the Hachiman-bori canal, Omi Hachiman’s famous tourist attraction, and hear from Ms. Masayo Shiraishi, deputy secretary general of the Omi Hachiman Tourism Association, about the canal’s history.

(2) Specified Non-profit Corporation Maruyoshi (Omi Hachiman): The History of Conservation of Lake Biwa

—Local residents’ efforts to improve the lake’s water quality

Lake Biwa provided water for daily life to the Kinki region, but from the late 1960s the dark side of the postwar economic miracle was seen in worsening water quality due to pollution. Wastewater from households and factories caused red tides and algae blooms, as well as tap water smelling strange and fish dying off in large numbers. Faced with this situation, in 1977 a grassroots “Soap Movement” began in Shiga Prefecture, calling for people to use powdered soap instead of synthetic detergents, and in 1979 the Ordinance for the Prevention of Eutrophication of Lake Biwa was enacted, a first of its kind in Japan. Initiatives to protect Lake Biwa through the local government and residents working together continue to form the foundation of environmental awareness in Shiga Prefecture today.

Mr. Yosuke Miyao, who founded the specified non-profit corporation Maruyoshi, carried out research on the water quality of Lake Biwa when he was a student, and is now involved in conservation efforts for reeds in Lake Nishinoko, a small lake nearby connected to Lake Biwa. Reeds are plants that grow along the shore and help purify water, as well as acting as a habitat for birds and fish, contributing to maintaining Lake Biwa’s ecosystem. However, if they are not sufficiently tended to they can rot and worsen water quality. Mr. Miyao works together with other residents to cut reeds and develop products made out of reed, such as whistles, paper, and internal packaging, aiming to preserve the culture and reeds, indispensable to Lake Biwa, as a local resource through management and utilization.

-

[Photo courtesy of Mr. Yosuke Miyao]

◆The tour will hear from Mr. Yosuke Miyao, director of the specified non-profit corporation Maruyoshi, about the characteristics of Lake Biwa, the history of the water pollution during the postwar economic miracle and following grassroots efforts for conservation, as well as Lake Biwa’s relationship with the development of industry, explaining how people in the area have lived alongside Lake Biwa over the years.

2. Saiki Sangyo Co., Ltd./FLOAT Co., Ltd. (Omi Hachiman)

—Continuing to culture freshwater pearls in Lake Biwa while responding to changes in the environment

Freshwater pearls are produced in Lake Biwa using a freshwater mussel species (Hyriopsis schlegelii). In 1930, the first freshwater pearls to be successfully cultured in Japan were made in Lake Biwa.

Saltwater pearls are made by inserting a core into the mollusk, while freshwater pearls are cultured by inserting a small tissue sample, with the pearl forming around it. The lack of a core leads to unique shapes and colors, and a natural sheen. Lake Biwa freshwater pearls are also highly regarded for their beauty in Europe, and there was a vibrant export business at one point.

Freshwater pearl production in Lake Biwa reached its peak in the 1980s, but with a worsening culture environment due to factors such as algae blooms and increasing availability of Chinese freshwater pearls starting in the 1990s, the industry rapidly declined. At one point, production dropped to approximately 14 kilograms per year, and there are currently six pearl farming companies remaining.

One of those, Saiki Sangyo Co., Ltd., has continued to farm freshwater mussels and produce freshwater pearls in Lake Nishinoko since 1959. Carrying out everything from production to processing and sales, they have continued producing freshwater pearls while responding in recent years to the effects of climate change, such as rising water temperatures and increasing amounts of algae.

Sales of Lake Biwa freshwater pearls are frequently limited to retailers with exclusive contracts, but Saiki Sangyo also provides pearls to individual accessory creators and others who value them. One such creator is Ms. Kaoru Sawa of FLOAT Co., Ltd.. Around ten years ago, Ms. Sawa began making accessories for daily use out of Lake Biwa freshwater pearls and the shells of the mussels, which were generally disposed of. In addition to selling them online, at events throughout Japan, and at shops selling local specialties, they were also chosen by the city of Maibara as a gift for the Furusato Nozei system.

Ms. Sawa hopes to spread awareness of the beauty of Lake Biwa freshwater pearls through her accessories, as well as promoting interest in the conservation of Lake Biwa, as water quality has a direct impact on farming mussels and the quality of the pearls.

-

[Photos courtesy of FLOAT Co., Ltd.]

◆The tour will hear about freshwater pearl production in Lake Biwa from Mr. Masakazu Saiki of Saiki Sangyo Co., Ltd., as well as hearing from Ms. Kaoru Sawa of FLOAT Co., Ltd. about making and selling pearl accessories. Afterwards, the tour will be able to see tissue being inserted into a freshwater mussel. The tour will then travel by motorboat to see the racks of mussels out in the lake.

3. Hon Nigorobuna Senmon Io (Azuchi)

—The first to succeed in farming Lake Biwa’s endemic crucian carp and preserve a historical local dish

Shiga Prefecture has a wide range of local dishes made with fish from Lake Biwa. One of the most famous is funazushi. Crucian carp (funa) with the innards removed is salted and then layered with cooked white rice in a barrel for a long period of time to ferment. Funazushi is a type of narezushi (fermented sushi) said to be the basis for modern sushi.

Funazushi was traditionally made with nigorobuna, a species of crucian carp endemic to Lake Biwa, but land reclamation projects to produce more rice during the postwar economic miracle, building concrete along the shore in areas with reed beds, and the introduction of invasive species led to a decrease in the catch. These days, crucian carp from outside the prefecture is increasingly used to make funazushi. Despite this, Hon Nigorobuna Senmon Io focuses on making funazushi using fatty nigorobuna. Ms. Masako Oshima, the head of Hon Nigorobuna Senmon Io, dug up some of her family’s farmland and made a pond using water from Lake Biwa, replicating the natural environment of Lake Biwa without using any chemicals and becoming the first to succeed in farming nigorobuna.

Following the traditional method of changing the water in the barrel daily when making funazushi, it has a less potent odor and a depth of flavor similar to cheese. It is said to pair well with not only sake, but also wine. Ms. Oshima also actively develops new products, such as dressings and pastes using the pickled rice from funazushi, in order to promote its appeal as a fermented food. Along with an increase in health consciousness, there has been growing interest in funazushi’s effects on the intestinal environment through lactic acid bacteria.

-

Pickling funazushi in a bucket

[Photos courtesy of Hon Nigorobuna Senmon Io]

◆The tour will hear from Ms. Masako Oshima, head of Hon Nigorobuna Senmon Io, about traditional methods for making funazushi, how they farm nigorobuna, and the health benefits of fermented foods. Afterwards, there will be an opportunity to try the company’s funazushi.

SMEs Nurtured by Mt. Ibuki, a Treasure Trove of Medicinal Plants

4. Yamasho Co., Ltd. (Nagahama)

—Contributing to the adoption of Eastern medicine through moxa made using traditional methods

Mt. Ibuki, the highest peak in Shiga Prefecture (1,377 m), appears in the Kojiki, written 1300 years ago and Japan’s oldest book, and was worshipped as being home to gods. Known for its medicinal plants, Oda Nobunaga also had a garden for medicinal plants opened on Mt. Ibuki on the advice of a Portuguese missionary. In particular, yomogi (mugwort) is common on Mt. Ibuki, and the fibers on the back of its leaves are used to make moxa, used in moxibustion*, which was well known in the Edo period as “Ibuki moxa.”

Yamasho Co., Ltd., a company which has been in Nagahama since 1895, is a manufacturer of acupuncture and moxibustion products which makes moxa using traditional techniques. Their high-quality products are well regarded, and acupuncture and moxibustion clinics around Japan use Yamasho products.

In recent years, they have also begun to be used in overseas acupuncture and moxibustion clinics in not only Asia, but in the US and Europe as well. Yamasho uses mugwort from overseas as well to make their moxa, but are now working together with local farmers on making moxa using only products from Shiga Prefecture. In 1992, Yamasho received a request from an acupuncture and moxibustion school in Nepal to confirm whether their local mugwort could be used for moxa, and visited Nepal. This led to them beginning to produce moxa in Nepal on a volunteer basis. In 2014, Yamasho founded a local company, and began a moxa production business alongside Nepali workers who trained in Japan at their head office. Today, that business has become an independent company, with the Nepali who trained in Japan having taken over, and is a business partner of Yamasho’s which continues to grow mugwort, while working to promote the adoption of acupuncture and moxibustion in Nepal.

*Moxibustion: An Eastern medicine practice involving burning moxa made from dried and processed mugwort leaves, placed directly or indirectly on the skin, in order to alleviate bodily ills.

-

[Photos courtesy of Yamasho Co., Ltd.,]

-

Moxibustion treatment

◆The tour will visit Yamasho Co., Ltd. and hear from company director Mr. Tatsuki Oshitani about the history of moxa production and the effects of moxibustion, followed by an opportunity to experience moxibustion. The tour will then go to the moxa factory and see how moxa is made.

5. Ibuki Farm Co., Ltd. (Maibara)

—Attracting people to the area through agriculture taking advantage of Mt. Ibuki’s environment

-

President Ryuichi Taniguchi with Ibuki daikon

[Photo courtesy of Ibuki Farm Co., Ltd.]

Heirloom crops such as Ibuki soba (buckwheat) and Ibuki daikon (radish) are grown around Mt. Ibuki. Ibuki soba was already grown there around one thousand years ago, in the Heian and Kamakura periods. The large temperature difference between day and night around the base of Mt. Ibuki is said to be a climate that helps bring out the sweetness and umami of crops.

Ibuki soba kernels are small and a lot of the husk is included when ground, so the flour has a strong aroma, but Ibuki soba also has a small yield and is ill suited to machine harvesting, so at one time production almost stopped entirely. In 1995, local farmers and Shiga Prefecture worked together to restart production using seeds donated from the surrounding areas. In 2019, “Ibuki Zairaisoba” was registered as a geographical indication (GI), in a successful revival of the local brand.

Ibuki Farm president Mr. Ryuichi Taniguchi began growing Ibuki soba and Ibuki daikon after leaving his job at the Maibara City Office. He also runs a soba restaurant, Kyujiro, out of a renovated traditional house at the base of Mt. Ibuki, which serves dishes using ingredients he grew himself. He even runs a leisure hotel facility, 3Re: (pronounced like “three”) with activities taking advantage of the local environment, such as barbecuing and saunas. With approximately 2,500 visitors a year, it is popular with overseas tourists and younger people from urban areas. Mr. Taniguchi has commented, “I would like to create jobs and stimulate the local economy by taking advantage of local resources, to protect rural areas from decline.”

◆The tour will hear from Mr. Ryuichi Taniguchi, president of Ibuki Farm Co., Ltd., about what led him to start growing local heirloom crops by Mt. Ibuki and his current businesses. The tour will then see Ibuki daikon being harvested from the field, and have soba made with grated Ibuki daikon for lunch at Kyujiro, a restaurant also run by Ibuki Farm. The tour will also see the hotel facility made from renovating a vacant traditional home.

Production with Traditional Methods of Silk Thread and Silk Strings for Instruments

6. Kinomoto-cho Society for the Preservation of Silk Strings for Japanese Musical Instruments (Tsukuda Heishichi Silk Reeling Workshop) (Nagahama)

—Passing on valuable techniques for making silk thread which have continued for a thousand years

Kinomoto, a town (administered by Nagahama, Shiga) at the base of Mt. Shizugatake, which overlooks Lake Biwa, has plenty of rain and snow. Mulberry trees, the leaves of which are used as feed for silkworms, grow well there, and silk thread has been made there since the Heian period (794 to 1185).

Even today, silk continues to be reeled by hand, soaking the cocoons in hot water and extracting the superfine threads one at a time and weaving them together. This traditional method of silk production retains a high level of a protein called sericin, creating strong silk threads. This strength makes them perfect for use with traditional Japanese stringed instruments. This technique is viewed as important to pass on to future generations, and has been designated as a Selected Conservation Technique by the Agency of Cultural Affairs.

The Kinomoto-cho Society for the Preservation of Silk Strings for Japanese Musical Instruments (commonly known as the Tsukuda Heishichi Silk Reeling Workshop) is the only workshop of its type remaining in the region. The workshop mostly uses cocoons made in Gifu Prefecture for its silk, but since 2014 local residents have been growing mulberry trees and raising silkworms. Through a process of trial and error, faced with difficulties such as the abnormal heat of recent summers, a total of around 20 kilograms of silkworm cocoons were produced this year. Silk is reeled from the cocoons in June and July every year, with all the raw silk produced delivered to Marusan Hashimoto (see next section).

With the increasing age of the silk reelers, there were concerns over passing on their techniques, but recently four younger women in their 30s and 40s, including some who relocated from other prefectures, are studying these traditional techniques.

-

[Photos courtesy of Ms. Masayo Tsujii]

-

◆The tour will hear from Ms. Mieko Tsukuda, the fourth-generation head of the Kinomoto-cho Society for the Preservation of Silk Strings for Japanese Musical Instruments (Tsukuda Heishichi Silk Reeling Workshop) about the tradition of raw silk production in the region, as well as speaking with the women who have decided to carry on the traditional techniques. Afterwards, the tour will be able to see and film/photograph raw silk being reeled from a cocoon.

7. Marusan Hashimoto Co., Ltd. (Nagahama)

—Using unique techniques to make the highest quality silk strings for instruments, trusted by professional musicians in Japan and around the world

-

【Photos courtesy of Mr. Gashu Toyosawa】

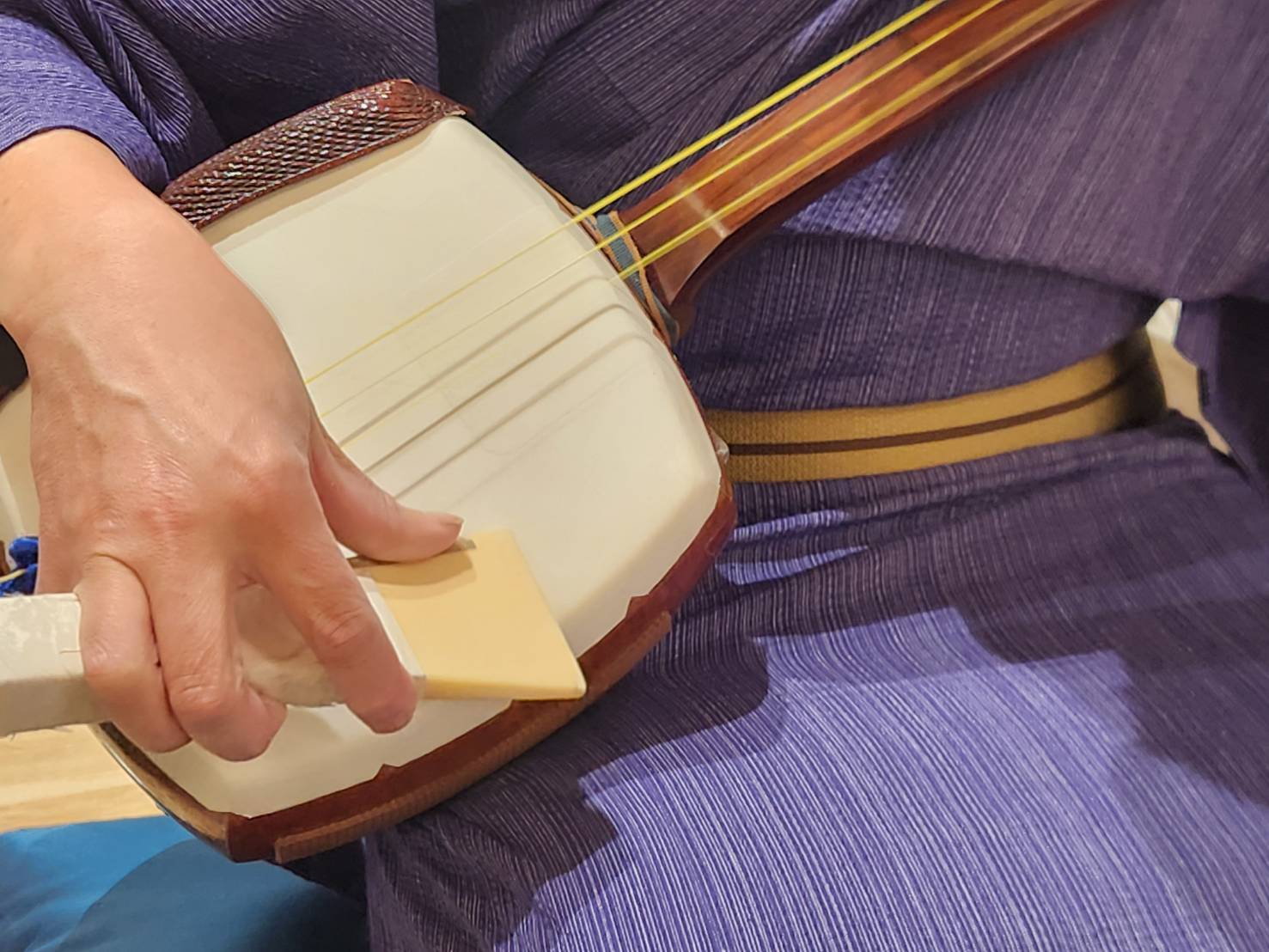

Marusan Hashimoto Co., Ltd. processes the raw silk from the Kinomoto-cho Society for the Preservation of Silk Strings for Japanese Musical Instruments (Tsukuda Heishichi Silk Reeling Workshop) into strings for Japanese instruments. The company has continued making strings for Japanese instruments such as koto and shamisen since its founding in 1908, and its strings are said to be used by the majority of professional musicians in the country who perform with Japanese instruments.

Marusan Hashimoto uses silk thread from producers such as the Kinomoto-cho Society for the Preservation of Silk Strings for Japanese Musical Instruments (Tsukuda Heishichi Silk Reeling Workshop) to make over 400 kinds of strings appropriate for a variety of instruments and performers. They are also the only company in Japan to use the traditional komayori technique to make strings out of silk thread. The degree of twisting of the thread is said to be important to the sound quality made by the strings, and artisans with expert technique produce the highest quality products.

In 2011, when Marusan Hashimoto exhibited at an international trade fair in Shanghai, someone involved in traditional Chinese instruments recognized the quality of their products, and so in 2013 they began exporting to China in earnest. They created an opportunity for the revival of the domestic silk instrument string market in China, which had been in decline. Since 2022, they have also been producing silk strings for gayageum, a traditional Korean instrument. Now, overseas exports including China and South Korea account for approximately 20% of Marusan Hashimoto’s sales.

-

[Photos courtesy of Marusan Hashimoto Co., Ltd.]

-

◆The tour will hear from Mr. Hidekazu Hashimoto, President of Marusan Hashimoto Co., Ltd. about the traditional techniques for making silk instrument strings passed down at the company, and see silk strings being made in the factory. Afterwards, the tour will be able to film/photograph a futozao (thick neck) shamisen performance using silk strings made by the company.

Tour Itinerary

1. Dates:

Thursday, November 27–Friday, November 28, 2025

2. Schedule:

[Thursday, November 27]

- 07:33-09:47

-

Tokyo Station→Maibara Station (Hikari 633)

- 11:00-12:45

-

Saiki Sangyo Co., Ltd./FLOAT Co., Ltd.

- 13:00-13:50

-

Lunch

- 14:00-14:50

-

Tour of the Omi Hachiman Municipal Museum (the former residence of the Nishikawa Clan)

/Tour of Hachiman-bori (Omi Hachiman Tourism Association)

- 15:10-16:30

-

Specified Non-profit Corporation Maruyoshi

- 16:50-17:50

-

Hon Nigorobuna Senmon Io

- 18:50

-

Arrive at hotel (in Nagahama)

[Friday, November 28]

- 09:10

-

Leave hotel

- 10:00-11:30

-

Yamasho Co., Ltd.

- 12:10-13:30

-

Ibuki Farm Co., Ltd./Lunch (Kyujiro, soba restaurant)

- 14:10-15:40

-

Tsukuda Heishichi Silk Reeling Workshop

- 16:00-17:20

-

Marusan Hashimoto Co., Ltd.

- 18:57-21:12

-

Maibara Station→Tokyo Station (Hikari 662)

3. Qualification:

Bearer of the Ministry of Foreign Affairs of Japan Press Registration Card (in principle)

4. Cost:

13,000 yen per person, including transportation, accommodation (breakfast included)

*Information on payment and cancellation fee will be provided to participants.

*Participants will be required to pay their own transportation costs to the meeting place before the tour, and after the tour ends

5. Participants:

Limited to 10 participants.

(Only one reporter or one photographer from each company, but two participants from each TV team will be acceptable.)

*Participants will be determined by the tour organizer.

6. Please be sure to confirm and agree to the following before applying

6-1. Basic Information

(1) This tour is organized by Shiga Prefectural Federation of Societies of Commerce and Industry and run by the FPCJ.

(2) The schedule is subject to change without notice.

(3) This tour will require participants to bear a part of the cost but is not a profit-making venture.

(4) Shiga Prefectural Federation of Societies of Commerce and Industry and the FPCJ take no responsibility for any accidents, injuries, illness, or other problems which occur during the tour.

(5) There may be some restrictions on photographing and filming at the tour sites. Please follow the instructions of the staff in charge.

(6) This press tour is intended to provide opportunities for news coverage. We request that all participants send a copy of the content of their coverage (article, video, or audio in the case of radio) to Shiga Prefectural Federation of Societies of Commerce and Industry through the FPCJ after their reports are published or aired. When your report is in a language other than English or Japanese, we also ask you to provide a summary in English or Japanese. By submitting your application, we assume that you have agreed to these conditions.

6-2.Handling of Personal Information

When applying for the tour, you agree to the below:

*Regarding the handling of personal information, the press tour organizers and operators will respect Japan’s Act on the Protection of Personal Information and all other laws and guidelines on the protection of personal information and handle personal information appropriately.

(1) The tour operators will, when there is a need to do so for the press tour, provide the personal information provided when applying (organization name, personal name, etc.) to other parties in the following cases:

-To arrange travel or insurance through travel agencies (Information provided to: Travel agencies, accommodation operators, transportation operators, insurance companies)

-To ensure smooth operations during the tour (Information provided to: Interpreters, stops on the tour, interviewees)

(2) The tour operators, to ensure smooth operation of the tour, will share the personal names and organization names of applicants with the tour organizers.

6-3.Recordings by Press Tour Organizers or Operators During the Tour

When applying for the tour, you agree to the below:

(1) For the record-keeping purposes, the tour operators may film or photograph the tour while it is happening. The copyright holders for these photos or videos will be the tour organizers.

(2) Photos, videos, or articles of the press tour may be uploaded to websites or social media accounts operated by the organizers or operators.

(3) The likeness or voice of participants may appear in the abovementioned photos or videos, but you agree to their use by the organizers or operators.

7. FPCJ Contacts:

Watanabe (Ms.), Yoshida (Ms.)

Media Relations Division

(Tel: 03-3501-3405, E-mail: ma@fpcjpn.or.jp)

◆When applying for the tour, you agree to the following conditions◆

- Press tours have participants from multiple media organizations, and interviews, filming, and photographing are generally carried out jointly. There is no guarantee that you will be able to perform individual interviews or take individual videos at any of the stops on the tour.

- You must follow the instructions of the tour organizers and operators regarding the tour schedule, timing, and restrictions on taking videos or photos. If you refuse to follow instructions, you will no longer be allowed to participate in the press tour from that point on.