実施日 : 2023年10月12日(木) - 13日(金)

Osaka Press Tour

投稿日 : 2023年09月22日

As there are already more applications for this press tour than there are positions available, we will be closing applications.

If you are still interested in applying, be aware that you will only be able to join if there are cancellations.

September 27, 2023

The Potential of Japan's Second Largest Industry and Economy

Osaka, the venue for Expo 2025 Osaka, Kansai

See Osaka from the skies / Learn about its industry and history

<Topics>

1. Expo 2025 Osaka, Kansai venue and World Heritage site: Film and photograph them from above in a helicopter

2. Companies using technology to provide solutions for issues caused by declining birthrates and a reduced work force

3. Unique local industries in southern Osaka

4. Osaka’s ancient history/Aerial hub for Expo 2025 Osaka, Kansai

On October 28 and 29, the G7 Trade Ministers' Meeting in Osaka-Sakai will be held. The Osaka, Kansai Expo is also planned to be held in 2025. The prefecture of Osaka has a gross product of around 39 trillion yen (as of FY 2020), making it the largest in Japan after Tokyo.

Southern Osaka is home to the Mozu-Furuichi Kofun Group (kofun=mounded tombs), including the Nintoku-tenno-ryo Kofun, the largest kofun in the world, which was built in the 5th century. This demonstrates how the region was already a center for Japanese authority at that time. In the Middle Ages, the area developed as a center for foreign trade, and prospered as the center of the Japanese economy at that time. The metalworking industry also developed in the area, starting with blades and firearms, and Osaka is now home to many manufacturing companies, including one of the world’s largest agricultural equipment manufacturers, which has the top market share in Japan.

Osaka Prefecture is home to around 270,000 SMEs, which account for 99.6% of businesses in the prefecture (as of FY 2016), and the vitality of these SMEs could be considered the driving force behind Osaka’s economy. In southern Osaka in particular, in addition to local industries such as traditional crafts and textiles, there are also unique SMEs such as one company which has developed a system for the restaurant industry using robots to cook and serve meals, in light of the declining workforce.

Ahead of the G7 Trade Ministers' Meeting in Osaka-Sakai, this press tour will visit southern Osaka, including Sakai and Minamikawachi, and cover unique companies there, as well as the area’s historical background. The tour will also take a helicopter to get a bird’s-eye view for filming and photographing Yumeshima, the venue for Expo 2025 Osaka, Kansai, and the Mozu-Furuichi Kofun Group World Heritage site in the same area.

[Tour Details]

<Topic 1: Expo 2025 Osaka, Kansai venue and World Heritage site: Film and photograph them from above in a helicopter>

1. Mozu-Furuichi Kofun Group and Expo 2025 Osaka, Kansai Venue

The Nintoku-tenno-ryo Kofun (in Sakai) is one of the kofun that compose the Mozu-Furuichi Kofun Group, and as the largest kofun in Japan, this World Heritage site is considered one of the “three great tombs of the world,” along with the Great Pyramid of Giza in Egypt and the Mausoleum of the First Qin Emperor in China. Thought to have been constructed in the mid-5th century, the kofun’s mound is 486 meters long, the largest in Japan, and has a unique keyhole shape. It is thought to be the tomb of a figure with significant authority in Japan at that time.

Expo 2025 Osaka, Kansai will be held for half a year from April 2025, with the theme of “Designing Future Society for Our Lives.” With the Expo being held in Osaka for the first time since 1970, 55 years ago, a large wooden roof is planned to be built at the venue as the symbol for the Expo. With a height of 12 m (20 m for the exterior) and an inside diameter of 615 m, this “Ring” will be one of the largest wooden structures in the world, and the pavilions will be built inside and around it. At Yumeshima, Osaka City’s artificial island that will be the venue, preparations are underway, such as constructing pavilions.

◆The tour will ride on helicopters to film and photograph the Nintoku-tenno-ryo Kofun and other kofun in the Mozu-Furuichi Kofun Group, the Expo 2025 Osaka, Kansai venue under construction on Yumeshima, and central Osaka from the skies.

(*Since the helicopter windows cannot be opened, all videos and photos will be through the window. The helicopter may be cancelled in the case of poor weather.)

Japan Association for the 2025 World Exposition staff will give a briefing on Expo 2025 Osaka, Kansai and the current preparations. Staff from the sponsor of this tour, 2023 Trade Ministers’ Meeting Osaka-Sakai Promotion Council Secretariat, will explain the Mozu-Furuichi Kofun Group and the role of local governments in the G7 Trade Ministers’ Meeting.

[Bottom photo: Expo venue under construction (*You will not be able to take the same photos from the helicopter.)]

【Bottom photo courtesy of Japan Association for the 2025 World Exposition】

<Topic 2: Companies using technology to provide solutions for issues caused by declining birthrates and a reduced work force>

2. Kubota Corporation Sakai Plant

—Global company using the power of technology to support agriculture in response to agricultural workers decreasing in number and aging

Kubota (head office: Osaka City) is a leading global agricultural equipment manufacturer, which creates products for both dry field and wet paddy agriculture. In addition to having the top domestic share among agricultural equipment manufacturers, Kubota also operates its business globally, meeting the needs of different countries and regions. With an overseas sales ratio of approximately 78% (2022), it also has the highest market share in the world for combines in Asia.

Having worked alongside farmers since its founding, Kubota has responded to the issues of the decline in the number of agricultural workers, their aging, and the lack of successors by making efficient production of high-quality agricultural products possible without requiring more labor. They included the latest technology in tractors, launching their Agri Robo Combine with an automatic driving assist function, along with the Agri Robo Tractor making unmanned automatic driving possible.

The Sakai Plant, the mother plant for Kubota’s machinery business, began operations in 1937 and now manufactures around 37,000 tractors of various sizes annually, which are exported around the world, mainly to the West and the rest of Asia. There is a research and development section in addition to the manufacturing section, and product and technology development is being carried out on engines and agricultural equipment for Japan and the world.

With 3000 employees, the plant has implemented initiatives to provide products to customers more rapidly, such as having automated carts provide parts to the production line in the engine production plant, reducing personnel hours and labor costs for transporting those parts, and making it so everyone can perform the same work without any mistakes. One engine is built every 20 minutes, with about 25 built in a day, and although the larger parts are made by machines, the more delicate assembly is performed by hand, allowing for the creation of highly accurate products.

◆The tour will hear from Mr. Junji Takeda, the manager of Kubota’s Sakai Plant, about the plant, Kubota’s global business, and initiatives to solve social issues through its business. The tour will also see the engine and tractor production lines, and have the opportunity to ride on a tractor.

*There will be some restrictions on filming/photographing in the plant (follow directions from staff regarding filming/photographing.)

3. HCI Co., Ltd. (Izumiotsu City)

—Developing a system for the restaurant industry, which workers are not returning to after the pandemic, where robots do everything from cook to serve customers

HCI Co., Ltd. is an SME founded in 2002 as an equipment manufacturer making products such as cables and wires. The company is known for a patented stranding machine that twists together cables thinner than hair for mobile phones. In 2008, they started their Robot System Integrator business to produce robot systems, and the next year delivered their first robot system to a customer. In 2017, they also began developing AI.

In recent years, HCI has been putting its efforts into developing systems to use robots in the service industry, such as restaurants. With the service industry falling into a slump during the COVID-19 pandemic, and workers still not returning, making it difficult for restaurants to continue operating, there has been more attention paid to robots in the restaurant and service industries than ever before. In 2022, HCI used the robot and AI systems it had developed in-house to establish the HCI Robo House café in its head office, the first café in the world where robots carry out everything from cooking to serving customers. In addition to being a cafeteria for company employees, the café also has a menu available for regular customers.

As the concept of the café is “robots cook and serve the food,” small industrial robot arms made by Kawasaki Heavy Industries heat, open, and plate retort pouches of curry and pasta, with a different robot providing salads and desserts. These robots place the food on a different server robot, manufactured overseas, which then brings the food to the table of the customers who ordered it. Another robot collects the dishes later. A similar robot café has opened at a facility near Haneda Airport, and has become a popular new spot to interact with robots. HCI president Mr. Koji Okuyama has stated, “It is necessary to create robot-friendly environments, like the Ministry of Economy, Trade and Industry has proposed,” as he strives towards “coexistence between robots and people.”

◆At the HCI Robo House, the tour will hear from HCI president Mr. Koji Okuyama about the company, the state of the robot market, and contributions to SMEs struggling with a lack of workers. There will also be an opportunity to film and photograph the robots preparing food, and then have that food for lunch. Following lunch, the tour will see the HCI Test Factory, a facility which has not only Japanese-made robots, but robots made overseas as well.

<Topic 3: Unique local industries in southern Osaka>

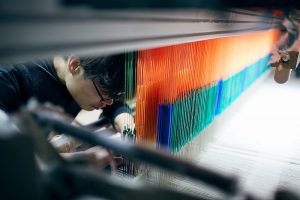

4. Sugita Seiren (Tondabayashi City)

—A contemporary master craftsman providing bamboo blinds to shrines and temples throughout Japan

Sudare are traditional Japanese blinds made from natural bamboo, used for centuries as dividers for rooms and to block the sun. Sudare’s origins lie in the Nara period (710–794), and in the Heian period (794–1185) elegant and high-class sudare, "misu", were used as dividers and decorations in the palace, as shown in The Tale of Genji.

Osaka Kongo sudare, named after the local Mt. Kongo, developed as a local industry in Tondabayashi in the Edo period (1603–1868). In 1996, they became the only sudare in Japan to be recognized as a traditional craft by the Minister of Economy, Trade and Industry. Sudare are made almost entirely by hand: first bamboo strands are made, then woven together, and finished.

Sugita Seiren is a long-standing Osaka Kongo sudare company, founded in 1839. As their skills are highly regarded, shrines and temples around the country use sudare from Sugita Seiren. The 6th generation president of the company, Mr. Koichi Sugita, is a traditional craftsman who was recognized as a Notable Skilled Worker (Contemporary Master Craftsman) for the Ministry of Health, Labour and Welfare in FY 2022, and he continues to maintain traditional handcrafting techniques while growing and managing a bamboo grove.

Although sudare are vital to shrines and temples, due to lifestyle changes and the availability of inexpensive foreign-made ones, demand has declined. Now, there are only five businesses making sudare in southern Osaka. However, with the recent trend of rediscovering the benefits of traditional crafts, Sugita Seiren has been working to create new demand, developing sudare book covers together with students from the Osaka University of Arts.

◆The tour will hear from Sugita Seiren president Mr. Koichi Sugita, and have the chance to film and photograph part of the process of a veteran craftsman making sudare. At the Sudare Museum, also located there, the tour will hear from Mr. Hiromasa Moriguchi, director of the Osaka Sudare Cooperative Association, about the history and current state of the sudare industry, and future plans, as well as looking around the museum.

5. Fukuroya Towel (Izumisano City)

—A small company with 9 employees, updating a local industry

A core local industry in the Senshu region in southwestern Osaka is towel-making, which developed thanks to ample underground water sources in the area and has over 130 years of history. The towels are unique for being made with an “atozarashi” process, in which the starch added to reinforce the threads and any impurities are washed out after the towel has been woven. This creates towels that are whiter, soft to the touch and allow the natural absorbency of cotton to shine through. The large quantity of wastewater made as a byproduct of towel manufacturing is filtered to a high degree and disposed of after being returned to clean water.

Senshu is the birthplace of towel production in Japan, but is not well known for making towels. Also, Japan imports the majority of its towels from Vietnam (47% in 2022) and China (46% in 2022), and so the industry is faced with tough competition regarding cost and quality compared to foreign towels.

Fukuroya Towel is a Senshu towel manufacturer founded in 1926. A small company with only nine employees, they have been working to differentiate themselves by providing added value to their products to build a brand. In particular, their SHIZUKU series uses unique techniques to dye the towels using ingredients such as the leftovers from making carrot juice, vegetables not fit for sale due to their shape, and waste leaves including those remaining after vegetables have been harvested. No bleach, fluorescent brighteners, or softeners are used, making these towels friendly to both users’ skin and the environment. In addition to being popular with consumers who prefer ethical consumption and natural materials, the towels were also sold in-flight by an airline at one time. Fukuroya Towel has also begun exporting their products to Australia, Hong Kong, Taiwan, the UK, and the US, and plans to continue to grow their focus on exports.

◆The tour will visit Fukuroya Towel and hear from its president, Mr. Kenji Fukuroya, about the characteristics of Senshu towels, manufacturing while being environmentally friendly, and plans for expanding overseas sales channels. The tour will then see the company’s workshop.

【Workshop interior photos courtesy of Fukuroya Towel】

<Topic 4: Osaka’s ancient history/Aerial hub for Expo 2025 Osaka, Kansai>

6. Osaka Prefectural Chikatsu Asuka Museum (Kanan Town, Osaka Prefecture)

The Chikatsu Asuka Museum is a specialized museum dedicated to “looking at the creation process of Japan’s ancient kingdoms and international exchange,” covering the Kofun and Asuka periods (3rd century to 7th century). Osaka has many ancient sites, not the least of which is Japan’s largest kofun, the Nintoku-tenno-ryo Kofun, showing that this was a central hub for authority during those times. This museum exhibits objects excavated from kofun and other sites in Osaka Prefecture, as well as easy to understand explanations of research, and the permanent exhibition has around 1500 objects, including swords, blades, and other metalworks.

First opening in 1994, the museum was designed by world-famous architect Tadao Ando, using his characteristic exposed concrete in a stylish and simple design. The building as a whole is reminiscent of a kofun, with a large staircase representing the afterlife, the Yomi Tower, covering the entire building. The museum had approximately 70,000 visitors in 2022, including foreign students studying archeology and international architecture fans.

◆The tour will hear from museum director Mr. Kazumi Tateno about the features of the museum, kofun culture, and local history, followed by seeing exhibits such as objects excavated from kofun, along with explanations from a curator.

*There are some restrictions on filming and photographing in the museum.

【Photos courtesy of Osaka Prefectural Chikatsu Asuka Museum】

7. Kansai International Airport (Izumisano City)

Opened in 1994, the Kansai International Airport is the first airport in the world to be made on a completely artificial island, built on five kilometers of reclaimed land in Osaka Bay. Praised not only for the techniques used in its construction, but also consideration shown for the marine environment, in 2001 it was selected by the American Society of Civil Engineers as one of 10 projects representing the 20th century, along with the Panama Canal. The airport aims to be an environmentally progressive airport, implementing various initiatives towards the three goals of decarbonization, a circular economy, and environmental coexistence. These initiatives cover a broad range, including using hydrogen energy for work vehicles inside the airport, installing solar panels, efficient use of water resources, and encouraging seaweed beds alongside the airport’s seawalls.

The Kansai International Airport is carrying out its first major renovation project since opening in 1994, and the international departure area will be reborn this winter. As the aerial hub for Expo 2025 Osaka, Kansai, preparations are underway to welcome visitors from Japan and around the world.

[Left photo: Image after renovation]

◆The tour will visit Kansai International Airport and hear from staff with its operating company Kansai Airports about initiatives to use hydrogen at the airport and progress on the renovations.

*The briefing will be in a conference room, and there will also be an opportunity to film and photograph from the observation hall where the runaways and terminal can be seen.

[View from the observation hall] [Aerial view of Kansai International Airport]

【Photos courtesy of Kansai International Airport】

[Tour Itinerary]

Dates: Thursday, October 12 to Friday, October 13, 2023

[Thursday, October 12]

06:51-09:15 Tokyo Station - Shin-Osaka Station (Nozomi #7)

10:30-12:30 Photographing from helicopter (3-4 persons per flight, 3 flights planned),

Briefing at Yao Airport

13:00-14:10 Kawachi Wine Konjikido (Lunch and fermentation facilities tour)

14:30-16:00 Osaka Prefectural Chikatsu Asuka Museum

16:20-17:50 Sugita Seiren

18:40 Arrive at hotel (overnight at Sakai)

★Day 1 Lunch

・Kawachi Wine Konjikido

A winery where food and culture can be enjoyed alongside wine. There will be an opportunity to see the fermentation facilities, followed by lunch at Konjikido, in what used to be a traditional Japanese warehouse.

Kawachi Wine Co., Ltd.: http://www.kawachi-wine.co.jp/index.html (Japanese only)

・When traveling from Yao Airport to Kawachi Wine, and from Kawachi Wine to the Osaka Prefectural Chikatsu Asuka Museum, the tour will travel along the Minamikawachi Fruits Road.

Minamikawachi Fruits Road (Osaka Prefecture website)

https://www.pref.osaka.lg.jp/minamikawachinm/m_index/k_fruitsroad.html (Japanese only)

【Friday, October 13】

08:30 Leave hotel

09:00-11:00 Kubota Corporation Sakai Plant

11:30-13:30 HCI Co., Ltd. (“HCI ROBO HOUSE” and “HCI TEST FACTORY)

Lunch at “HCI ROBO HOUSE”

14:00-15:30 Fukuroya Towel

15:50-17:30 Kansai International Airports (briefing by Kansai Airports and photographing from the observation hall)

18:40-19:55 Kansai International Airport – Haneda Airport (ANA3828)

3. Qualification: Bearer of the Ministry of Foreign Affairs of Japan Press Registration Card

4. Cost: 15,000 yen per person, including transportation, accommodation (breakfast included), and lunches (for both days)

*Information on payment and cancellation fee will be provided to participants.

*Participants will be required to pay their own transportation costs to the meeting place before the tour, and after the tour ends.

5. Participants: Limited to 10 participants.

(Only one reporter or one photographer from each company, but two participants from each TV team will be acceptable.)

6. FPCJ Contact: Yamada (Ms.), Watanabe (Ms.)

Media Relations Division

(Tel: 03-3501-3405, E-mail: ma@fpcjpn.or.jp)

7. Remarks:

(1) This tour is sponsored by 2023 Trade Ministers’ Meeting Osaka-Sakai Promotion Council and run by the FPCJ.

(2) The schedule is subject to change without notice.

(3) This tour will require participants to bear a part of the cost, but is not a profit-making venture.

(4) 2023 Trade Ministers’ Meeting Osaka-Sakai Promotion Council and the FPCJ take no responsibility for any accidents, injuries, illness, or other problems which occur during the tour.

(5) There may be some restrictions on photographing and filming at the tour sites. Please follow the instructions of the staff in charge.

(6) Please be aware that videos and photos of the tour, and articles about it, may be posted by 2023 Trade Ministers’ Meeting Osaka-Sakai Promotion Council and the FPCJ on their websites or social media.

◆When applying for the tour, you agree to the following conditions◆

- Press tours have participants from multiple media organizations, and interviews, filming, and photographing are generally carried out jointly. There is no guarantee that you will be able to perform individual interviews or take individual videos at any of the stops on the tour.

- You must follow the instructions of the tour sponsor and operators regarding the tour schedule, timing, and restrictions on taking videos or photos. If you refuse to follow instructions, you will no longer be allowed to participate in the press tour from that point on.